|

Waste to

Wealth Creation

India contributes to 17.7% of the world’s population; which is expected to grow to 1500 million by 2030 and 1600 million by 2047, making it the most populated nation in the world (BMTPC, 2018). Population, urbanisation and income growth is expected to increase over the next few decades which will increase material consumption. Simultaneously, waste generation will also increase multiple fold. A detailed study on the solid waste generation in India conducted by Pappu et al. (2007) estimated that 960 million tonnes of solid waste (hazardous or non-hazardous) is generated in India annually during different processes which include industrial, mining, agricultural and municipal activities. Several efforts are being made across the country to utilise different streams of waste and use them as alternative materials in different sectors to reduce the burden on virgin natural resources and safeguard the environment from unethical disposal of waste. In this article, we will focus on one such waste stream, the Kota stone waste which is generated as a byproduct of the mining sector. Kota stone is primarily a calcareous rock of sedimentary origin which generally consists of 68 to 70% calcium carbonate and 23 to 25% silica. Kota and Jhalawar districts of Rajasthan and Neemuch district of Madhya Pradesh are the major producers of Kota stone dust. It was estimated that Kota stone production amounted to 80 lakhs million tonnes per annum. Out of this about 4 to 5 lakh million tonnes is fine dust generated from quarrying, crushing and polishing which is dumped in surrounding agricultural fields, road sides and forest lands (Hussain and Perez, 2015).

As Kota stone dust is a good source of carbonate, it can be used as a replacement for limestone in ternary blends (Krishnan et al., 2018; Weerdt et al., 2011). Ternary cements have been gaining importance due to their improved performance and synergistic benefits on using in combination with supplementary cementing materials (SCM). In ternary cements, low clinker factor can be achieved by replacing clinker with industrial wastes (Jittin et al., 2020). Limestone calcined clay cement or LC3 is one such ternary cement, in which clinker factor of 0.50 has been achieved by partially replacing clinker using a combination of calcined clay and limestone (Avet et al., 2018; Emmanuel et al., 2016).

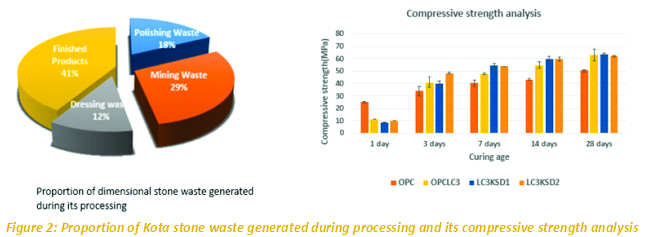

To meet the economic goals without affecting the climate mitigation goals of the nation, shift to alternative technologies and use of waste along with conventional technologies becomes crucial. As cement production leads to degradation of the environment in many ways, use of Supplementary Cementitious Materials (SCMs) as a substitution of clinker could be a solution for the demand of cement to be met. The use of SCMs must be assessed locally based on their availability and properties. Thus, in the current research study, Kota stone dust has been used as a replacement of limestone in producing LC3 cement. Two different blends were prepared with 16% Kota stone dust (LC3KSD1) and 23% Kota stone dust (LC3KSD2). Refer to Figure 2. With the increase in the amount of Kota stone dust from 16% to 23%, the early strength increases and the later age strength is approximately similar, hence we can increase the amount of Kota stone dust without compromising on its compressive strength. The analysis is that we can utilise waste Kota stone dust in place of limestone as there was no effect observed on the compressive strength at various ages. ■

References: 2. Emmanuel, A. C., Haldar, P., Maity, S., & Bishnoi, S. (2016). Second pilot production of limestone calcined clay cement in India: the experience. Indian Concr. J, 90, 57-64. 3. Hussain, A., & Perez, I. (2015). V.,“Kota stone slurry problem and possible solution”. 4. Jittin, V., Rithuparna, R., Bahurudeen, A., & Pachiappan, B. (2020). Synergistic Use of Typical Agricultural and Industrial By-products for Ternary Cement: A Pathway for Locally Available Resource Utilisation. Journal of Cleaner Production, 123448. 5. Krishnan, S., Emmanuel, A. C., Kanaujia, S. K., & Bishnoi, S. (2018). Hydration and mechanical properties of limestone calcined clay cement produced with marble dust. In Calcined Clays for Sustainable Concrete (pp. 249-253). Springer, Dordrecht. 6. Pappu, A., Saxena, M., & Asolekar, S. R. (2007). Solid wastes generation in India and their recycling potential in building materials. Building and environment, 42(6), 2311-2320. 7. Utilisation of Recycled Produce of Construction and Demolition Waste: A Ready Reckoner (BMTPC, 2018) 8. Weerdt, K., Haha, M. B., Le Saout, G., Kjellsen, K. O., Justnes, H., & Lothenbach, B. (2011). Hydration mechanisms of ternary Portland cements containing limestone powder and fly ash. Cement and Concrete Research, 41(3), 279-291.

Aayushi Agrawal, Neha Agarwal

|