|

Reducing the Environmental

Sustainable

development means any development that is attained without the depletion

of natural resources. In this context, the construction industry is

focusing on using alternate solutio Cement is the main constituent of concrete, which is responsible for the major greenhouse gases emissions. Additionally, its production is highly energy intensive. Embodied energy or energy required to produce concrete in a RMC plant varies with the type of cement, transportation distance of the cement, aggregates and admixtures used. As the transportation distance increases, more fuel will be used and consequently the energy required and the emissions produced increase. Concrete mix with lower cement content will have lower embodied energy and emissions. Also, use of locally available aggregates can reduce the negative impact of concrete.

In India, the total energy required in the

production of Ordinary Portland Cement (91% clinker) is about 4722 KJ

and total emissions are 820 kg CO2 eq. per kg of cement where

85% of the energy and 94% of the emissions are associated with the

production of clinker. Increasing the use of blended cements using

byproducts like fly ash, slag etc. helps in the reduction of clinker

content and also reduces the waste deposition on land. One way to do

this is with the use of Limestone Calcined Clay Cement (LC3),

in which the clinker content is only 50%. The remaining 35% is calcined

clay and 15% is limestone. The reduction in clinker content helps in

considerably reducing emissions of greenhouse gases and energy consumed.

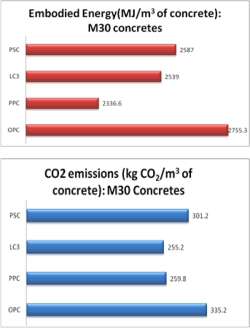

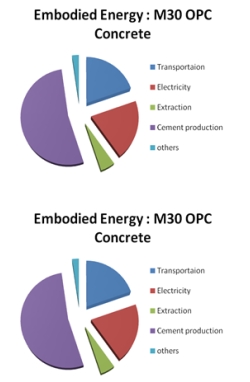

The lifecycle assessment (LCA) of a typical case of use of concrete in India, where concrete was assumed to be produced in Chennai, reveals that cement content and type of cement has major role in the total emissions and embodied energy of concrete. In an Ordinary Portland Cement (OPC) concrete with a strength of 30MPa, 75% of the total emissions and 50% of the total embodied energy is due to cement production. Other major contributing processes are transportation and electricity generation. The contribution of major processes in concrete production are shown in the graph. Different concrete mixes with different binders like Portland Pozzolana Cement (PPC) (fly ash 30%), Portland Slag Cement (PSC) (15% Slag) and LC3 with a strength of 30MPa at 28 days were also studied and compared with OPC concrete. The results show that there is a considerable reduction in energy consumed and CO2 emissions when alternate binders are used. The lowest CO2 emissions is in case of LC3 concrete and embodied energy of LC3 concrete is less than that of OPC and PSC concrete. OPC concrete has highest embodied energy and CO2 emissions as shown in the graph. Owing to the large consumption of concrete, small reductions in GHGs can make a difference in the global scenario and therefore should be mandated so that the energy consumed and the resources used in the production of concrete are minimised. ■

Anusha S B Reference:

|

ns for materials resulting in

sustainable practices. Concrete is one of the most widely used materials

in construction. It

accounts for around 5-8% of the man-made CO2 emissions. India

is the second highest concrete consuming country in Asia. Aggregates,

which constitutes 80% to 90% of the concrete are having significant

environmental impacts such as resource depletion, energy consumption,

greenhouse gas emissions etc.

ns for materials resulting in

sustainable practices. Concrete is one of the most widely used materials

in construction. It

accounts for around 5-8% of the man-made CO2 emissions. India

is the second highest concrete consuming country in Asia. Aggregates,

which constitutes 80% to 90% of the concrete are having significant

environmental impacts such as resource depletion, energy consumption,

greenhouse gas emissions etc.