|

Indian Plastic Recycling Technologies:

Opportunities and Challenges

India is among the largest consumers of plastic products in the world. It generates approximately 9.4 million tonnes of plastic waste each year (MoHUA, 2019; Hossain, Islam, Shanker, et al. 2022). The plastic industry of the country currently comprises 15 large polymer factories, nearly 30,000 manufacturing units, and over 7,000 recycling units employing more than 4 million people (Hossain, Islam, Shanker, et al. 2022; Jaganmohan, 2020; IBEF, 2021). The Indian plastic industry comprises approximately 2,000 exporting companies, 150 plastic processing machinery producers, and over 30,000 processing units (Neto, Gomes, Pertel, et al. 2021). An analysis by Plastindia Foundation (www.plastindia.org) indicates the compound annual growth rate of the industry at 10.5% during five financial years (FY 15 to FY 20) reaching a yearly production of 22 million metric tonnes (Hossain, Islam, Shanker, et al.2022; Plastindia Foundation, 2018). This increase may further be driven by different initiatives being promoted by the government, such as Make in India, Skill India, Digital India, and the Swachh Bharat Abhiyan (Bhattacharya, Chandrasekhar, Deepthi, et al.2018; Mohanty, 2017).

India's massive boom in plastic consumption is attributed to fast demographic growth, perpetual growth in consumerism, industrial progress, rapid urbanisation, new consumption trends aided by the spread of supermarket chains, and increasing inclination towards e-commerce and food delivery applications (Pillai, 2021). Its large networks of unlicensed manufacturing units produce surplus quantities of low-quality, cheap plastic bags, which is the key reason why India produces an enormous amount of plastic waste (Banerjee, 2019). Simply banning unauthorised recyclers or even competing with them as well as banning the problematic plastic use will not solve the Indian plastic waste issue. It is an ever-growing problem that needs cross-departmental cooperation. The future of Indian plastic waste management heavily relies on the efficacy of local government, recyclers, and community involvement.

Common recycling technologies adopted by manufacturers in India

Source - Shanker, Khan, Hossain, et al, 2022

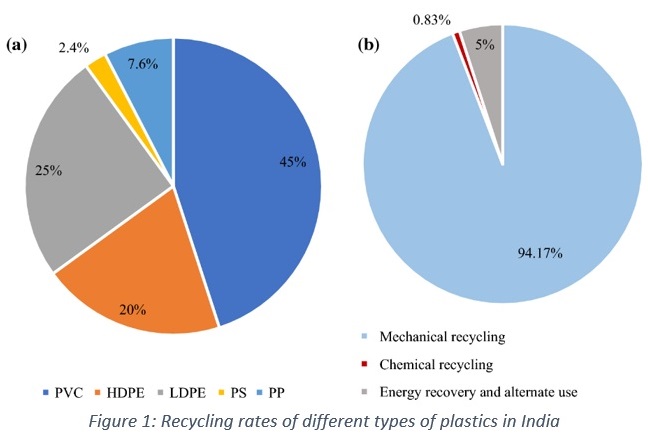

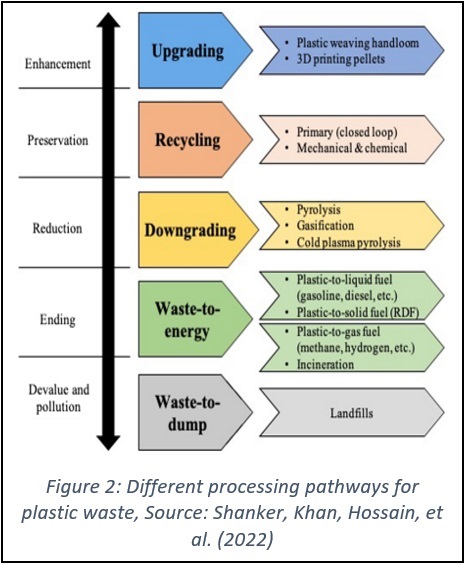

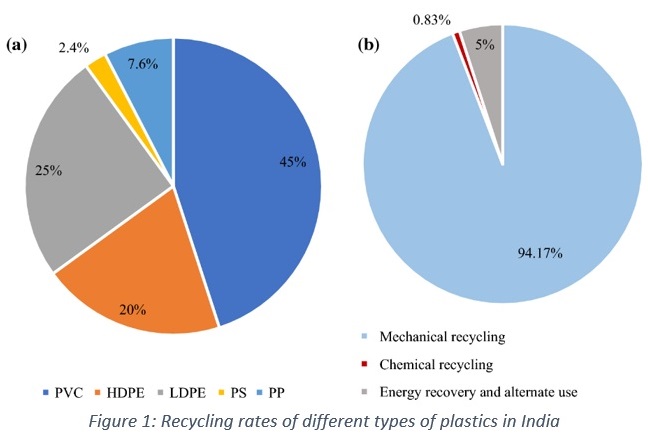

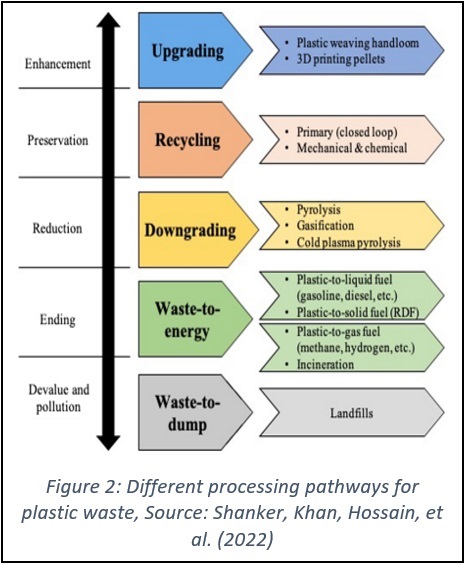

Several techniques of plastic waste recycling are adopted by the formal and informal Indian plastic waste manufacturers, such as depolymerisation, pyrolysis, and remanufacturing of the other products. Chemical recycling industries are at the developing stage in India as seen in the few examples of pyrolysis technologies to yield industrial-grade fuel oil, whereas the use of gasification for plastic waste is still lacking.

Rudra Environmental Solutions and Keshav Sita Trust have adopted a thermo-catalytic depolymerisation strategy where waste plastics are converted into fuel and syngas. APChemi uses the pyrolysis technique to convert waste plastics, tyres, and biomass into fuel and carbons. Fuel production via pyrolysis of waste plastics is a common technique in India that has been adopted by several companies, such as Paterson's Energy and PolyCycl. PolyCycl also employs a recycling strategy to convert discarded grocery bags and ketchup bottles and upcycles these to food-grade plastics. The delamination of the multi-layered food packaging is also adopted by PolyCycl by using the separating chemical agent to recover the aluminium and polyethylene (PE).

Most of the technologies of chemical depolymerisation are at the pilot stage with a single chemical recycling industry, Polygenta Technologies Limited, involved in depolymerisation of polyethylene terephthalate (PET) into oligomers of low molecular weight oligomers. The Department of Science and Technology (DST) under the Ministry of Science and Technology of the Government of India has adopted the latest technology to convert polystyrene (PS) into a non-woven fabric using the organic waste of citrus peel extract. PET bottles are also converted into yarn by units such as Gem Enviro Management Pvt Ltd, DST, and JB Ecotex LLP, which are then integrated with yarns of natural fibre and waste cloth. Shayna Ecounified India Pvt Ltd and RecycleX, among others, are converting waste plastics into High-Density Composite Polymer (HDCP™) tiles, bricks, paver blocks, kerbstones, benches, etc. Most of the technologies of chemical depolymerisation are at the pilot stage with a single chemical recycling industry, Polygenta Technologies Limited, involved in depolymerisation of polyethylene terephthalate (PET) into oligomers of low molecular weight oligomers. The Department of Science and Technology (DST) under the Ministry of Science and Technology of the Government of India has adopted the latest technology to convert polystyrene (PS) into a non-woven fabric using the organic waste of citrus peel extract. PET bottles are also converted into yarn by units such as Gem Enviro Management Pvt Ltd, DST, and JB Ecotex LLP, which are then integrated with yarns of natural fibre and waste cloth. Shayna Ecounified India Pvt Ltd and RecycleX, among others, are converting waste plastics into High-Density Composite Polymer (HDCP™) tiles, bricks, paver blocks, kerbstones, benches, etc.

The market for bio-plastics in India is witnessing a positive opportunity where multiple industries have actively joined the race for end products composed of bio-plastics. In recent advances, an Indian company, J&K Agro Industries Development Corporation Ltd, has signed a partnership with Earthsoul to establish India's first bio-plastics plant with an annual production capacity of 960 metric tonnes. Other manufacturers of bio-plastics in India include Ecolife in Chennai, Ravi Industries in Maharashtra, Truegreen in Ahmedabad, and Biotec Bags in Tamil Nadu. Among these players, Truegreen has an annual bio-plastics production capacity of about 5,000 tonnes.

Futuristic recycling, reformed manufacturing prospects, and challenges

The high growth rate of plastic consumption and stringent regulations propel everyone to explore alternative strategies. In India, bio-plastics are mainly manufactured using sawdust, corn starch, vegetable fats and oils, and wooden chips, whereas in the rest of the world bio-plastics are mainly synthesised using sugarcane, corn starch, and castor oil. The common manufacturing technologies and methods for bio-plastics comprise blow moulding, injection moulding, thermoforming, extrusion, and blow film extrusion. However, substituting bio-plastics for petrochemical-based plastic packaging would raise the danger of negative environmental consequences.

Increased usage of bio-plastics will necessitate a substantial quantity of land and water resources, putting pressure on other activities and negatively impacting the ecosystem. Other significant environmental effects of bio-plastics include toxic chemicals leaching from plastics during decomposition, emissions of PM10 from sugarcane conversion, and a lack of properly researched and integrated life cycle assessment methodologies relating to the negative effects of microplastics on the environment. Thus, technological advancements such as the following could be used to bring bio-plastics into the chain:

(1) Improving yields and decreasing the dependency on agrochemicals for feedstock production; (2) moving to second- and third-generation feedstocks; (3) improvements in energy efficiency and utilisation of renewable energies in the bio-refineries; (4) increasing the conversion efficiencies in bio-refineries; and (5) further improving the end-of-life management (e.g., recycling the bio-plastic wastes).

The price of biodegradable plastic products is higher than their synthetic plastic counterparts. Hence, tax exemptions, subsidies, and incentive-based mechanisms are necessary to help boost the market for these products. The focus for these plastics should be more on ‘bio-based content’ rather than ‘biodegradability’. As the market demand increases, there will be a growing need for an adequate supply of biomass feedstock. Research funding must focus on the development of innovative biodegradable products with an emphasis on performance, technology development, shelf life, and related financial aspects.

Chemical upcycling is a desirable approach that provides new advances to deal with real-world plastic wastes, specifically those that cannot be recycled by mechanical methods. It has the potential to valorise plastic waste into value-added products such as gaseous (hydrogen, hydrocarbons, and syngas), liquid (acids and fuels), and solid (carbonaceous materials including carbon black, activated carbon, carbon fibres, fullerenes, carbon nanotubes, graphene), which have additional practical and economic benefits. Various selective catalytic depolymerisation methods are studied for the transformation of PET into monomers. Development of selective hydrogenolysis can yield jet-fuel and lubricant-range hydrocarbons at a better yield (Hou, Zhen, Qian, et al. 2021). New energy-efficient catalysts, macromolecular transformations, and chemical processes have been investigated to achieve more efficient, selective, and low-energy processes for upcycling of waste plastics (Zhuo and Levendis, 2014). Photocatalysis is emerging as a promising approach for upcycling of plastics waste. The use of alternative energy sources is also gaining a considerable attention. The use of microwave technology for the thermal valorisation of polymers instead of traditional energy sources received much attention to reduce energy consumption (Karimi Estahbanati, Kong, Eslami, et al. 2021).

A recent study looked into the development of concrete mixture additives that use plastic waste as partial aggregates during the concrete making process. The investigation for this research was carried out with the help of the assessment of laboratory-based conclusions. Researchers have discussed the properties and features of plastic aggregate and plastic fibre to meet the requirements of aggregates and reinforcement metals. The emerging technologies of 3D printing using waste plastics with small-scale customised factories could be an opportunity for the 3D printed product for home decor and furniture in India (SMaRT@UNSW, 2020). Traditional recycling is regarded as a high-volume producer whereas 3D printing represents low volume and high value.

Green design of plastic products for sustainable recycling

The eco-friendly design of products is conducive to addressing the recycling issue after they become scrap. So, it is important to incorporate eco-friendly design, manufacturing and environmental protection, environmental behaviours, and consumer psychology while designing plastic products. The environmental attributes of the product, removability, recyclability, maintainability, reusability, etc. should be carefully considered in product design from the beginning to the final disposal of plastic waste. In research and development, manufacturers must give importance to the selection of sustainable materials, product structuring, and eco-friendly design so that the products can be easily recycled when they become scarp. Plastic product producers should be encouraged by the government to carry out eco-friendly designs and production to extend the lifespan of plastic goods, reducing plastic waste at the source.

The production, use, and disposal of some of the problematic plastic waste, such as e-waste and packaging, are all inevitable. Recycling plastic waste is necessary, but it must be done in a safe workplace with high standards. If possible, plastic waste can be refurbished as new products instead of used for resource purposes. If not refurbish-able, it should be sorted and processed by well-paid and sufficiently equipped professionals. The un-standardised additives, persistent organic pollutants, fumes contained, and contamination level in the surrounding environment of plastic waste garbage should be strictly monitored and controlled. Eco-friendly and green plastic waste collection and disposal techniques should be developed for recycling.

Manufacturers must consider the end-of-life impact of the product at the design stage itself. Decisions on the colours, additives, coatings, etc. of the final product should be made keeping the recycling issues in mind. There is a lack of testing and certification facilities to assess the quality of recycled plastic products. Research funding should be directed towards quality, performance, and the inclusion of environmentally benign additives leading to the development of novel products. Mapping of waste streams is essential to concentrate on commodity plastics and their tonnage in the recycling streams, which may lead to a circular economy for India's plastic waste. Consumers should also be educated by various forums, including educational sectors and communities to increase awareness regarding plastics and the ensuing waste disposal issues.

The chemical community, both industry and academia, should collaborate with governments, stakeholders, and society to tackle social, economic, and environmental issues around plastic use. Taking a holistic view that considers each step of the value chain and implementing integrated approaches that highlight innovation should achieve meaningful progress toward addressing the challenges and issues of bio-plastics and fossil-based plastics in India.

References

- Banerjee, A. 2019. Why does India report only half the plastic waste it generates every year? Business Standard 2 April, 2019. Details available at https://www.business-standard.com/article/current-affairs/why-does-india-report-only-half-the-plastic-waste-it-generates-every-year-119040200120_1.html

- Bhattacharya, R.R.N.S., Chandrasekhar, K., Deepthi, M.V., Roy, P., and Khan, A. 2018. Challenges and opportunities: Plastic waste management in India. Details available at https://www.teriin.org/sites/default/files/2018-06/plastic-waste-management_0.pdf, last accessed on 26 June, 2022

- Hossain, R., Islam, M.T., Shanker, R., Khan, D., Locock, K.E.S., Ghose, A., Schandl, H., Dhodapkar, R., and Sahajwalla, V. 2022. Plastic waste management in India: Challenges, opportunities, and roadmap for circular economy. Sustainability 14(8): 4425

- Hou, Q., Zhen, M., Qian, H., Nie, Y., Bai, X., Xia, T., Rehman, M. L. U., Li, Q., and Ju, M. 2021. Upcycling and catalytic degradation of plastic wastes. Cell Reports Physical Science 2(8): 100514

- India Brand Equity Foundation (IBEF). 2021. Indian plastics industry and exports.

- Jaganmohan, M. 2020. Plastic industry in India - statistics and facts.

Karimi Estahbanati, M.R., Dr Kong, X.Y., Dr Eslami, A., Prof. Dr Soo, H.S. 2021. Current developments in the chemical upcycling of waste plastics using alternative energy sources. ChemSusChem 14(19): 4152–4166.

- Ministry of Housing & Urban Affairs (MoHUA), Government of India. 2019. Plastic waste management: Issues, solutions & case studies. Details available at http://swachhbharaturban.gov.in/writereaddata/SBM%20Plastic%20Waste%20Book.pdf?id=8ahvmaemgz3crbbh, last accessed on 26 June, 2022

- Mohanty, S. 2017. Recycling of plastics in indian perspective. UNIDO Office: New York, NY, USA

- Neto, A.M., Gomes, T.S., Pertel, M., Vieira, L.A.V.P., and Pacheco, E.B.A.V. 2021. An overview of plastic straw policies in the Americas. Marine Pollution Bulletin 172: 112813

- Pillai, J. 2021. Managing plastic waste – what emerging economies like India can learn from developed nations. Details available at https://www.uflexltd.com/pdf/MI/2021/UFlex_Coverage_RP_JPillai_June21.pdf, last accessed on 26 June, 2022

- Plastindia Foundation. 2018. Report on the Indian plastics industry.

- Shanker, R., Khan, D., Hossain, R., Md. Islam, T., Locock, K., Ghose, A., Sahajwalla, V., Schandl, H., and Dhodapkar, R. 2022. Plastic waste recycling: Existing Indian scenario and future opportunities. International Journal of Environmental Science and Technology pp. 1–18

SMaRT@UNSW. 2020. Filaments. Details available at https://www.smart.unsw.edu.au/technologies-products/microfactorie-technologies/filaments, last accessed on 26 June, 2022

- Zhuo, C. and Levendis, Y.A. 2014. Upcycling waste plastics into carbon nanomaterials: A review. Journal of Applied Polymer Science 131(4)

Dr Rumana Hossain1

r.hossain@unsw.edu.au

Dr Sushma Pardeshi2

pardeshisushma@gmail.com

Affiliations:

1Research Associate, Centre for Sustainable Materials Research & Technology, SMaRT@UNSW, University of New South Wales (UNSW), Sydney, Australia

2Senior Project Associate, Environmental Biotechnology and Genomics Division, CSIR-National Environmental Engineering Research Institute (NEERI), Nagpur, India.

Back to Contents

|

Most of the technologies of chemical depolymerisation are at the pilot stage with a single chemical recycling industry, Polygenta Technologies Limited, involved in depolymerisation of polyethylene terephthalate (PET) into oligomers of low molecular weight oligomers. The Department of Science and Technology (DST) under the Ministry of Science and Technology of the Government of India has adopted the latest technology to convert polystyrene (PS) into a non-woven fabric using the organic waste of citrus peel extract. PET bottles are also converted into yarn by units such as Gem Enviro Management Pvt Ltd, DST, and JB Ecotex LLP, which are then integrated with yarns of natural fibre and waste cloth. Shayna Ecounified India Pvt Ltd and RecycleX, among others, are converting waste plastics into High-Density Composite Polymer (HDCP™) tiles, bricks, paver blocks, kerbstones, benches, etc.

Most of the technologies of chemical depolymerisation are at the pilot stage with a single chemical recycling industry, Polygenta Technologies Limited, involved in depolymerisation of polyethylene terephthalate (PET) into oligomers of low molecular weight oligomers. The Department of Science and Technology (DST) under the Ministry of Science and Technology of the Government of India has adopted the latest technology to convert polystyrene (PS) into a non-woven fabric using the organic waste of citrus peel extract. PET bottles are also converted into yarn by units such as Gem Enviro Management Pvt Ltd, DST, and JB Ecotex LLP, which are then integrated with yarns of natural fibre and waste cloth. Shayna Ecounified India Pvt Ltd and RecycleX, among others, are converting waste plastics into High-Density Composite Polymer (HDCP™) tiles, bricks, paver blocks, kerbstones, benches, etc.