India’s Future Needs for

Resources

in Construction

I

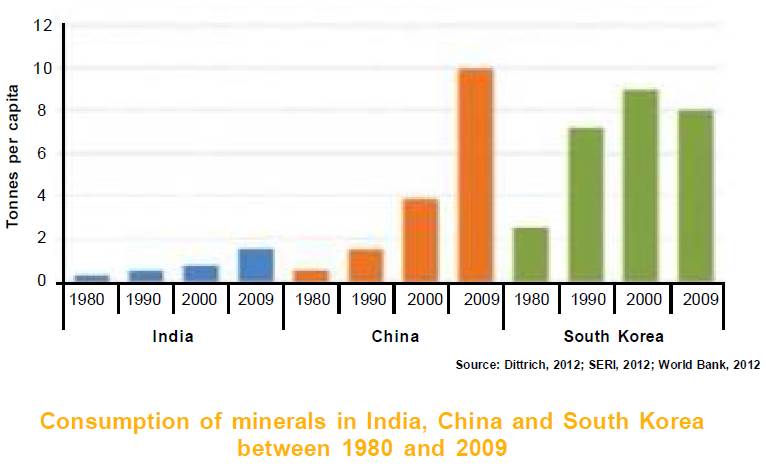

n developing countries like India, which are in the throes of rapid development, housing and infrastructure development have come to play a crucial role. Housing investments are made for several decades, or even for centuries. Given the volume of these investments, it is essential to consider the monetary aspects seriously before taking further steps. It is also advisable to consider the material aspect of the investments: location, design of houses, choice of building materials and several other factors that determine the consumption of natural resources such as land, water and air, as well as of scarce materials, not only during the construction phase of a building but also during the operation and demolition phases. To a large extent, decisions about the material aspects determine future investments in materials that are essential for running and maintaining the building. For example, the amount of energy required for heating and cooling the building is determined in particular by the building’s insulation. Thus, a country like India facing rapid development in the housing and infrastructure sector has an opportunity to choose and move on a material and natural resource efficient path for decades ahead and possibly even for the next century.Currently, the consumption of minerals is around 1.5

tonnes per capita, which is a remarkable five-fold increase since 1980.

Nevertheless, comparison with China or South Korea, two countries that have

invested large amounts in housing and infrastructure in the past few

decades, indicates how the consumption of construction minerals might change

in the following decades given the forecasted demand for housing.

Focusing on all the materials used in the construction sector (building and infrastructure), it is seen that the construction sector is one of the most material-intensive sectors. In India, the construction sector was the second largest sector with regard to material consumption in 2007, accounting for around 20% of all the material demand [SERI, 2012]. Further, the construction sector has been the fastest growing sector with regard to increase in absolute material consumption. Between 1997 and 2007, material consumption grew by more than one billion tonnes. If this trend continues, in the years to come material consumption in the construction sector will outweigh material consumption in the agricultural sector, the sector with the highest level of material consumption so far.

The predominant materials used in the construction sector are minerals, in particular bulky ones such as sand and gravel. However, between 1997 and 2007, the share of metals used in the construction sector increased more rapidly (around +400%) than the share of fossil fuels (around +70%), reflecting, amongst other things on the increasing energy efficiency within the sector and the more intensive use of structural metal elements in construction. Of the semi-processed construction materials, energy intensive materials such as cement and steel constitute large amounts of the components being used in the construction industry.

Buildings can be constructed using a variety of materials. The material composition of Indian buildings, that is, in floors, walls and roofs, as presented in the official census, involves a variety of materials. The choice of the materials used to construct the wall can influence the material efficiency of the building not only during the construction phase but also during the operational phase.

Given the housing demand in India, the potential future savings in terms of resource efficiency are immense in absolute values. Even if the average living space were to remain constant, the possible savings in primary raw material demand could exceed one billion tonnes – based only on the choice of the materials used for the walls. On the other hand, the raw material demand for building materials, electricity consumption, water consumption and disposal could only be 1.56 billion tonnes if the buildings were built in the most resource efficient way among the analysed options, resulting in a saving of 1.4 billion tonnes in required raw materials, including a saving of 697 million tonnes in building materials and a saving of 700 million tonnes in material input for electricity consumption.

(An excerpt from India’s Future Needs for Resources: Dimensions, Challenges and Possible Solutions in Construction, November 2013) q

Dr. Monika Dittrich

monika.dittrich@ifeu.de

Reference

http://www.igep.in/live/hrdpmp/hrdpmaster/igep/content/e48745/e50194/e58089/ResourceEfficiency_Report_Final.pdf