|

Limestone Calcined Clay

Cement: It is now well understood that the most viable alternative to reduce the CO2 impact of cement (and therefore, concrete) is the use of supplementary cementing materials (SCMs). The reduction in clinker factor of cement can also prolong the life of limestone reserves, making it possible to continue using cement as a major binding material for concrete. Among the available SCMs, the only ones that are potentially available in significant quantities are fly ash, calcined clay and limestone. The large-scale use of fly ash is hampered because of the high degree of variability in the properties of fly ash, making the overall availability of suitable fly ash limited. While calcined clay or limestone can only be used at relatively low replacement levels (10 to 25%), the combination of calcined clay and limestone has presented a possibility of large replacement of cement clinker. The blend of limestone and calcined clay in a ternary combination with cement results in a significantly improved performance of mortars and concretes because of: (i) Formation of new hydrated phases leading to an improved micro-structure with low porosity at early ages and (ii) Improved particle packing leading to a dense system. A recent collaborative project between Ecole Polytechnique Federale de Lausanne (EPFL) in Switzerland and IITs - Delhi, Madras and Bombay along with TARA, the social enterprise wing of the Development Alternatives Group in India, has looked extensively at the production and performance of such blended cementitious systems called Limestone Calcined Clay Cement or LC3.

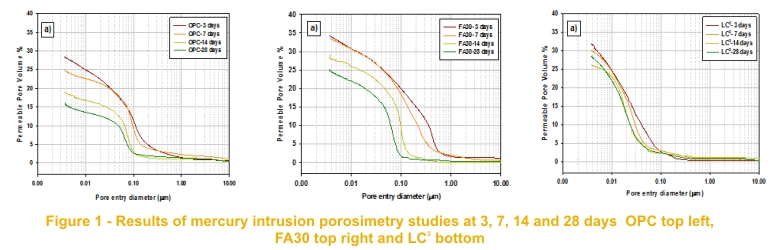

The development of the

denser pore structure in LC3 systems is depicted in the

results of mercury intrusion studies in Figure 1. Pores are classified

as capillary pores (inter-particle spaces, large 10 Ám - 50 nm and

medium 50-10 nm), gel pores (fine pores between hydrates, 10 nm 2.5 nm)

and interlayer pores (within the hydrates, < 0.5 nm). Based on this

assessment, it is clear that the LC3 system has more of the

finer pores, indicating a greater amount of the hydrated gel, as

compared to the fly ash system. This shift to finer pores happens as

early as 3 days. While there is almost no difference between LC3

and OPC systems at 7 days, the fly ash system is able to achieve

equivalent dense structure only after prolonged curing. Studies on

compressive strength development with the three binder systems also

showed that a lower cementitious materials content and higher w/c in LC3

concretes was able to produce equivalent strength in concrete.

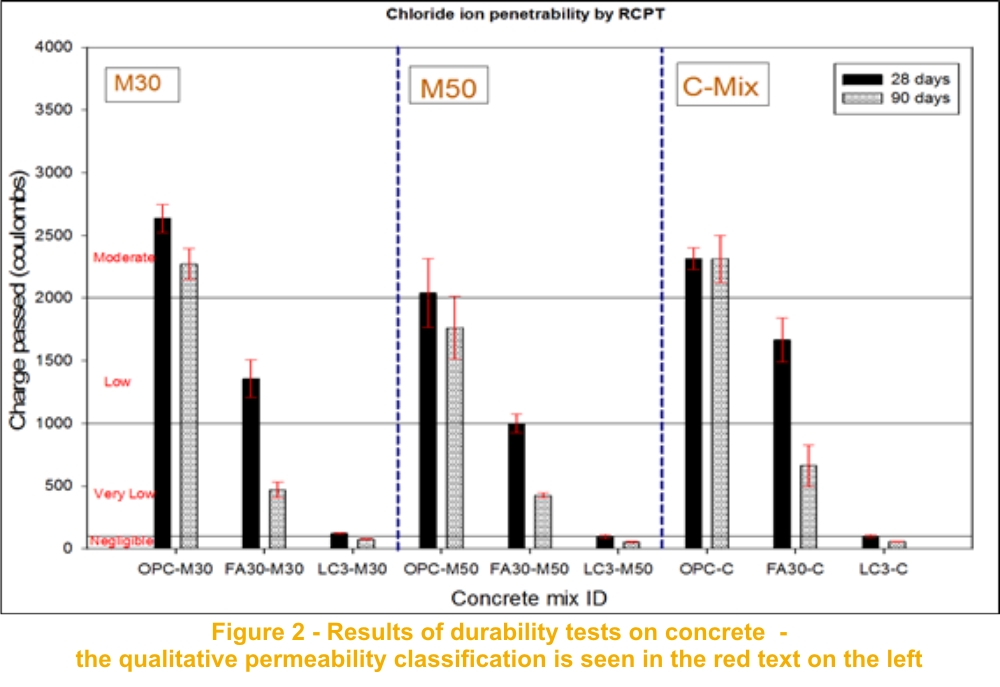

The benefits of the

denser pore structure were also seen in the durability results. The

charge passed in 6 hours in the Rapid Chloride Permeability Test (RCPT)

as per ASTM C1202, for ordinary strength grade (M30 M50) concretes with

LC3, was in the 'Negligible' range (see Figure 2), indicating

a performance level comparable with ultra high strength concretes that

have very low w/c (< 0.20). In comparison, the fly ash concrete was only

able to reduce the permeability to the 'Very Low' level, that too only

by 90 days. The rapid chloride permeability test is only one major

indicator of the level of durability. Several other durability tests

conducted at IIT Madras, including the Rapid Migration Test, Oxygen

Permeability Test, Water Sorptivity Test, and Bulk Diffusion Test - all

pointed to a superior durability attained with the LC3

binder. In short, the performance of concrete with LC3, in an

environment which promotes chloride induced corrosion, is superior to

that of concrete made with plain OPC, or even with a fly ash based

concrete. The one possible negative could be the performance of LC3

binder in carbonation prone environments. This occurs

in polluted areas, under specific conditions of humidity (usually RH

between 50 and 70%). Carbonation leads to a gradual reduction in

alkalinity of the concrete, and creates the depassivation of reinforcing

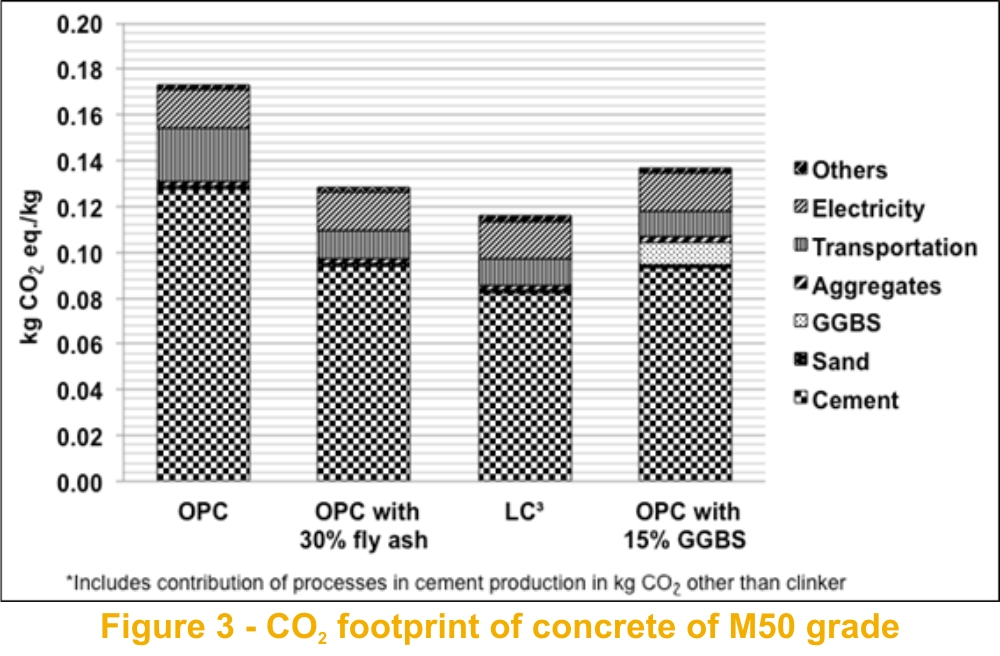

steel leading to its corrosion. Howeve While there are several positives in terms of durability performance, the real benefit of using the LC3 binder is realised in the CO2 footprint of the concrete. Figure 3 shows the CO2 emissions per kg of concrete produced for concretes with OPC, 30% fly ash, LC3 and 15% slag. It is clear from the data that the major contribution to the emission is from the cement component in concrete and the lowering of emissions with LC3 in an equivalent grade of concrete is significant as compared to OPC and better than for fly ash and slag based concretes. In conclusion, there is tremendous potential for the use of LC3 in concrete, but there are several more steps before this technology can be properly implemented. These include the standardisation of cement, addressing the issues related with selection of materials and production and showcasing the technology in demonstration structures. Further, the true environmental impact over the service life of a concrete structure in practice needs to be ascertained. Efforts to standardise the cement in India are ongoing. The cement companies have a crucial role to play in up scaling of this technology. The current phase of the collaborative project aims to address these issues. ■

Manu Santhanam Endnotes

|

r, the lower permeability of the

concrete with LC3, combined with the high resistivity of the

system, would even cause a lowering of the corrosion potential in such

environments. Extended studies to assess the corrosion of reinforcing

steel in carbonation prone conditions are currently under way.

r, the lower permeability of the

concrete with LC3, combined with the high resistivity of the

system, would even cause a lowering of the corrosion potential in such

environments. Extended studies to assess the corrosion of reinforcing

steel in carbonation prone conditions are currently under way.