|

Capacity Building for a T he quest for alternative models of sustainable growth to address the global challenges of natural resource depletion and mitigating carbon emissions has led to the evolution of new green products and services. Routing investments in green technologies and business models can bring out innovative products that can revolutionise many sectors of the industry, mainly, the ones that are most resource and energy intensive like the construction sector.This is one of the fastest growing sectors in India today. It is solely responsible for emitting about 22 per cent of India’s total annual CO2 emissions. It’s impact on resources is set to increase further due to the rapid economic growth in India, driven by increasing population, rising income levels, increasing urbanisation rates along with the rise in per capita consumption of materials thereby adding immense pressure on the finite natural resources. Currently, the per capita consumption of materials in India is around 1.5 tonnes, which is a remarkable fivefold increase since 1980 and if the trend continues, the construction sector will have the highest levels of material consumption in India within a decade (IGEP, 2013). The combined challenges of climate change and exploitation of natural resources urges us to deviate from the current path adopted by the sector and look for different options and alternate modes of economic growth that are most resource-efficient and which have the lowest environmental impact. Approaches to Resource Efficiency Resource efficiency (RE) can be simply defined as ‘creating more with less’. In broad terms, it is a way of delivering more with less resource inputs in a sustainable way thus minimising the impact on the environment. RE has always remained a priority in the policy agenda around the world as countries realise its significance for transitioning to a green economy. Use of secondary raw materials is seen as a practical approach to achieving resource efficiency through decoupling of critical building materials. A secondary raw material can be anything ranging from waste from another industry or an alternate building material available in nature that could be substituted in place of a critical resource (e.g. sand, stone and gravel). Construction and Demolition (C&D) waste is one such secondary raw material which offers great recyclability potential for utilisation in various construction applications. Focus on Non-Technological Developments Current innovations fostering resource efficiency tend to focus primarily on technological advances and solely focusing on such technical developments will not make a greater impact. Non-technological drivers such as local capacity building and training have often played a prominent role in driving these innovations further while complementing these technological changes. For instance, diffusion of green technologies whether it be solar or biomass technologies, to regions could fail over time if local capacities were not developed for local manufacturing, repairing, operating and maintaining the facilities. Evidence from various sources suggests that successful technology development and diffusion have often emphasised the need to develop and strengthen local capacities. Why is Investing in People Important? The industrial shift to adopting resource efficiency brings out new opportunities for growth which demands new set of skills and failing to bridge the skills gap can seriously hamper the growth of the industry. Capacity building lays a solid foundation for effective and efficient functioning of activities. It is a broad term which encompasses a multitude of activities ranging from strengthening processes, systems and rules that influence collective and individual behaviour and performance to enhancing people’s technical ability and willingness to play new developmental roles and adapt to new demands and situations (UNEP, 2002). Drivers of Skill Change As economies go green, the need for skilled jobs

arises. It is very important to understand the basic drivers of skill

change to predict the future training needs and jobs (ILO, 2011). Major

drivers of skill change identified by experts have been listed below.

Existing Policies and Initiatives The amendment to the existing Municipal Waste Management Rules, 2015 is aimed at the proper streamlining of C&D waste management in India. Unlike the existing rules where no specific guidelines were given for the management of C&D Waste, the new version included the responsibilities and timelines for implementation for all stakeholders involved with the management of C&D Waste. Also, as part of the Swachh Bharat Mission in India, policy interventions have been initiated for C&D Waste management and recycling on a national scale. These new rules set a benchmark for C&D waste management, but it is critical that capacity development is imparted to each stakeholder for proper implementation and monitoring of these rules. Key Challenges Major challenges in capacity development that were

highlighted during the transition to resource efficiency in the

construction sector are as follows: Key Actions and Recommendations To create an enabling environment and encourage the

industrial shift to adopting resource efficiency, the following set of

actions have been recommended: Krishna Chandran References: • UNEP (2002), Capacity building for sustainable development; An overview of UNEP environmental capacity building activities. • IGEP (Indo-German Environment Partnership) (2013), India’s Future Needs for Resources: Dimensions, Challenges and Possible Solutions. New Delhi: GIZ. • GIZ (2015), International Workshop on Securing Sustainable Resource Utilisation and Reuse of Secondary Raw Materials by Fostering Resource Efficiency, New Delhi. • Kristensen, P. (2004), The DPSIR Framework, National Environmental Research Institute, Denmark Department of Policy Analysis European Topic Centre on Water, European Environment Agency. • ILO (International Labour Organisation) (2011), Skills for green jobs: Global view, Synthesis report based on 21 country studies, Geneva, pp 13. • RE- SEEties, Policy recommendations paper on resource efficiency, http://www.re-seeties.eu/

|

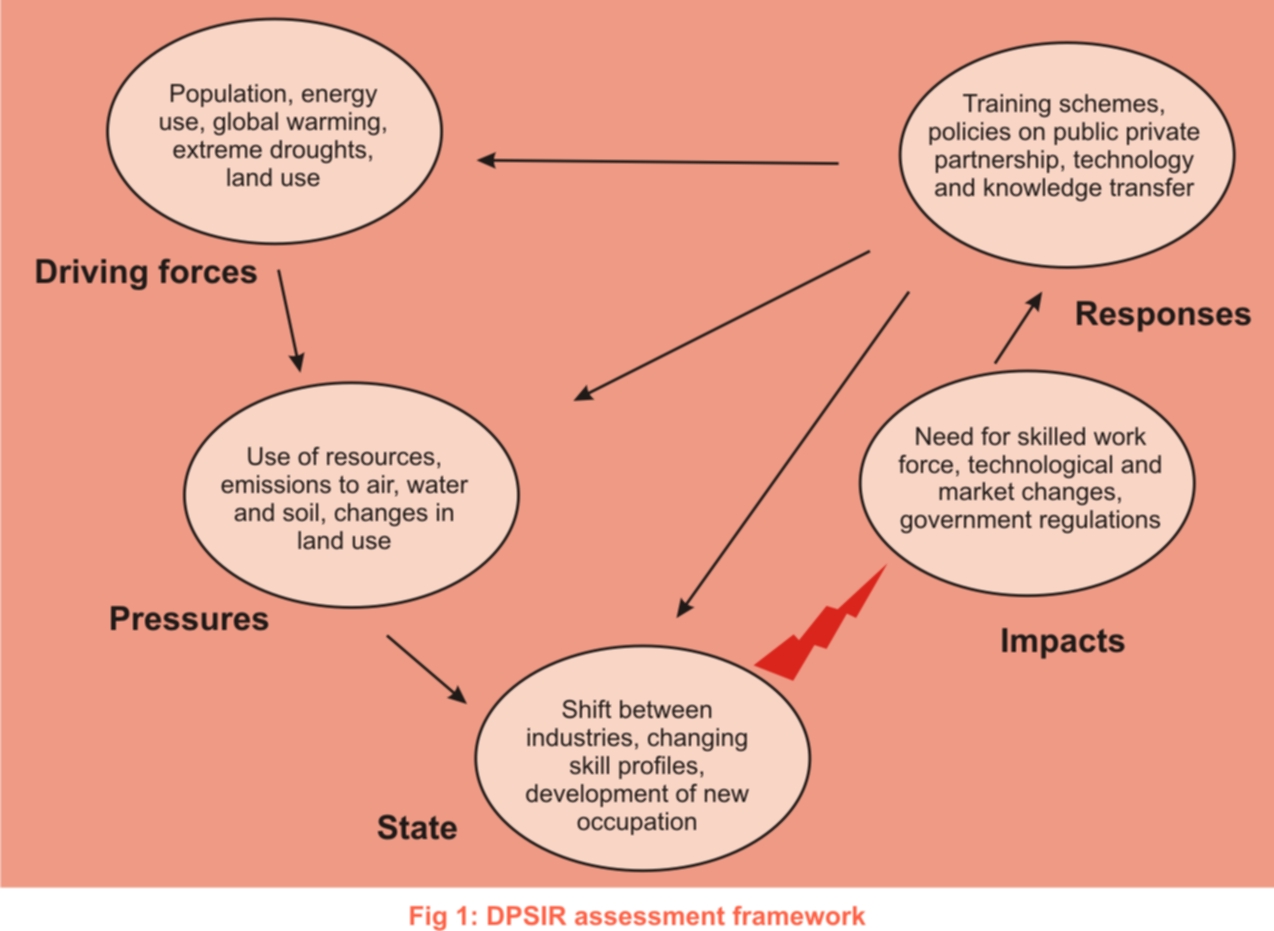

Figure 1 explains the components of the DPSIR

(Driving Forces-Pressures-State-Impacts-Responses) framework in the

context of capacity development for resource efficiency in the

construction sector. A ‘driving force’ is basically a need such as a

need for food, water, energy and housing. The human activities performed

towards meeting these needs results in excessive use of natural

resources which exerts ‘pressures’ on the environment causing different

types of emissions to the air, water and soil. The changes in the

physical, chemical or biological state of the environment may have

environmental or economic ‘impacts’ on the functioning of ecosystems

resulting in shifting from traditional production processes to

innovative technological processes to avoid further damage to the

ecosystem. The ‘impacts’ observed as a result of changes in the

industrial systems demand changes in the economy, educational skills,

training and other social aspects. This in turn demands a ‘response’

from society or policy makers.

Figure 1 explains the components of the DPSIR

(Driving Forces-Pressures-State-Impacts-Responses) framework in the

context of capacity development for resource efficiency in the

construction sector. A ‘driving force’ is basically a need such as a

need for food, water, energy and housing. The human activities performed

towards meeting these needs results in excessive use of natural

resources which exerts ‘pressures’ on the environment causing different

types of emissions to the air, water and soil. The changes in the

physical, chemical or biological state of the environment may have

environmental or economic ‘impacts’ on the functioning of ecosystems

resulting in shifting from traditional production processes to

innovative technological processes to avoid further damage to the

ecosystem. The ‘impacts’ observed as a result of changes in the

industrial systems demand changes in the economy, educational skills,

training and other social aspects. This in turn demands a ‘response’

from society or policy makers.