|

TARA EcoKiln Is well on its way to commercial success!

Apart from business development major innovations has been done on technological front namely:

n Utilization of Sponge Iron Waste to reduce coal consumption

Breakthrough has been made at the TARA EcoKiln in Champa, Chattisgarh, where sponge iron waste has been partially substituted for soil resulting in enviable external coal savings. The plant is now consuming 2 tonnes of coal per lakh of fired bricks compared to 18 tons of coal used in traditional movable chimney BTK.

n Utilization of Fly Ash as a substitute for soil

25% fly ash has been added to soil for making green bricks using mechanized mixing at Raigarh plant in Chattisgarh. The results have been remarkable. Sound of bricks has been significantly improved with a metallic sound hitherto unheard of in this area. There is no perceptible change in colour.

n Enhancement in quality of bricks using mechanized mixing

Technology has been put to good use in Muniguda, Orissa. With the use of Pugmill, soil is being mixed to a consistency not possible by conventional manual mixing techniques. This process allows use of any waste material during green brick production. Use of Pugmill has resulted in reduction of breakage from 5% to 2% with a significant increase in consistency of fired brick quality.

n

Enhancement in

quality of bricks using TARA Brick Mech

One of the recent addition to the technology portfolio is the semi automatic brick moulding machine – The TARA Brick Mech; which can produce green bricks in consistent shapes and sizes using unskilled workers. Efficiency of the machine has resulted from the compactness of the design and ability to be transferred to soil available locations. All the actions of benchmark soil processing, e.g. grinding, watering, pugging has been inbuilt into the system. The TARA Brick mech produces approximately 1200 bricks per hour using 8 unskilled workers. Apart from making frogged bricks, use of this machine reduces firing breakage and does away with the need of expert moulding skills.

n Cost reduction in civil construction of plant

A TARA EcoKiln brick entrepreneur at Sehore, Madhya Pradesh has achieved 30% cost saving using a RCC frame structure instead of masonry load bearing structure used in most plants. The initiative opens up the possibility for new plants to be constructed using the frame structure.

For the coming season focus will be on complete mechanization of brick production so that TARA EcoKiln becomes the only total end-to-end solution for new brick entrepreneurs towards 365 days of brick production. q

Rajeev Gupta

|

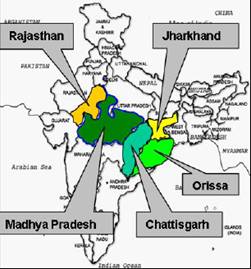

he brick season ending June

2006 was a successful year for TARA EcoKilns. A total of 40 plants were

operated during the year. All the kilns have been commercially built by

aspiring brick entrepreneurs. Success of the TARA EcoKiln technology was

in terms of enviable coal savings, flexibility of production and firing

of bricks in 24 hours; features that no other traditional brick firing

technologies can deliver. TARA has established plants in Madhya Pradesh

(18), Chattisgarh (8), Jharkhand (4), Rajasthan (2) and Orissa (5). In

addition, kilns have been installed in Karnataka, Uttar Pradesh and

fired successfully. TARA has also been successful in establishing tie up

with the Industry Department, Government of Jharkhand and Orissa for

inclusion of TARA EcoKiln technology under the prevailing Margin Money

Scheme of Khadi Gram Udyog. In Chhattishgarh, State, Khadi Gram Ugyog

has taken initiatives to organize workshop in all districts for wider

dissemination of this eco friendly and profitable technology.

he brick season ending June

2006 was a successful year for TARA EcoKilns. A total of 40 plants were

operated during the year. All the kilns have been commercially built by

aspiring brick entrepreneurs. Success of the TARA EcoKiln technology was

in terms of enviable coal savings, flexibility of production and firing

of bricks in 24 hours; features that no other traditional brick firing

technologies can deliver. TARA has established plants in Madhya Pradesh

(18), Chattisgarh (8), Jharkhand (4), Rajasthan (2) and Orissa (5). In

addition, kilns have been installed in Karnataka, Uttar Pradesh and

fired successfully. TARA has also been successful in establishing tie up

with the Industry Department, Government of Jharkhand and Orissa for

inclusion of TARA EcoKiln technology under the prevailing Margin Money

Scheme of Khadi Gram Udyog. In Chhattishgarh, State, Khadi Gram Ugyog

has taken initiatives to organize workshop in all districts for wider

dissemination of this eco friendly and profitable technology.