ne of the main environmental problems confronting the state of Orissa is the reduction of harmful emissions and safe disposal of huge quantities of industrial waste materials being generated. The situation is going to be aggravated by the active initiatives to promote processing and manufacturing units in new industrial clusters. In the State of Orissa there are about 130 sponge iron units in clusters. A 100 MT sponge iron unit produces approximately 15 – 20 MT of char per day. These char cannot be used in any profitable unit due to its low calorific value. Thus disposing it, is the only solution adopted at present. The TARA EcoKiln (Vertical Shaft Brick Kiln) technology can provide a solution for profitable utilization of these waste materials by brick producers. Technology choice: Why TARA Eco Kiln? The TARA EcoKiln is an appropriate technology solution to conventional Bulls Trench Kiln (BTK) and open clamps. Development Alternatives has been instrumental in introducing it to India in 1996 initially at Datia, Madhya Pradesh. After initial adaptation to Indian soil conditions it is now being commercially disseminated in the states of Orissa, Chattisgarh, Madhya Pradesh and Rajasthan. The design of the TARA EcoKiln resembles an intermittent updraft kiln having a unique method of continuous brick firing. The EcoKiln accomplishes a building like structure with a life span of more than 15 years. Within a roofed and buttressed rectangular support building are two, four or even six well insulated shafts according to the desired production capacity. The firing shaft is rectangular in cross-section with a nominal size of 1mx2m and approximately 5.5m height. The inner side of the firing shaft is lined with refractory bricks to provide maximum heat resistance as well as to ensure exact verticality for trouble free operation. The gap between refractory shaft walls and outer kiln walls is filled with insulating materials. The firing shafts are open at the top and bottom. At the base of each shaft is an arched tunnel, which runs throughout the kiln allowing access to both sides of the base of the firing shaft for unloading the fired bricks. To monitor the position of the fire, peep holes for placing thermocouples are provided along the shaft height. The advantages of TARA EcoKiln: n High energy efficiency The TARA EcoKiln technology economizes on fuel costs, with savings of between 30 to 50% when compared with other common brick firing technologies such as clamps or Bulls Trench Kiln with movable chimneys. n Environment friendly operations The construction of a TARA EcoKiln requires very little land. The building of multiple shaft production units further enhances the ratio of land use to production output. As a TARA EcoKiln can only be fired with coal (or with coal dust), deforestation of rural areas can be controlled. Additionally, if a TARA EcoKiln is operated as per recommended conditions, emissions are reduced by approximately 90% compared to common traditional brick firing technologies. n Economically viable Brick production using TARA EcoKiln technology is a profitable business and the overall initial investment is low (considering investment in permanent land). Since in a TARA EcoKiln the fired bricks are produced in 24 hours so the working capital required is much less. n Uniform quality of production Unlike other brick firing technologies where a uniform quality of fired bricks is not possible due to heat losses, in TARA EcoKiln the batches of fired bricks produced are 95% uniform in quality segregated into a single class. Compared to the Bulls Trench Kiln where 2nd and 3rd grade bricks are produced in significant quantities, a VSBK produces mostly 1st grade bricks. Breakage and wastage can be limited to even less than 5% through stable operation of the TARA EcoKiln and quality green brick making. n Round the year production The TARA EcoKiln can be operated all the year round and even during monsoon time subject to availability of dried green bricks. Weather factors have only a minor influence because a roof protects the kiln. n Consistent quality TARA EcoKiln produces high quality bricks if proper firing practices are followed. In fact, the products are even superior to those of existing rural brick production technologies (traditional and BTK firing technologies). TARA EcoKiln fired bricks show a fine, deep red colour with a good, metallic ring depending upon the soil quality. A compressive strength of upto 200 kg/cm2 can be achieved using good quality soils. The process

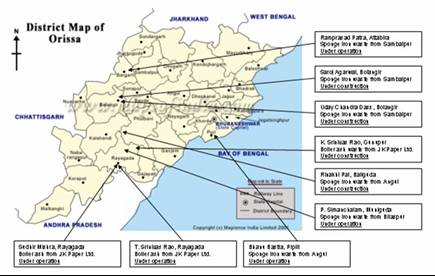

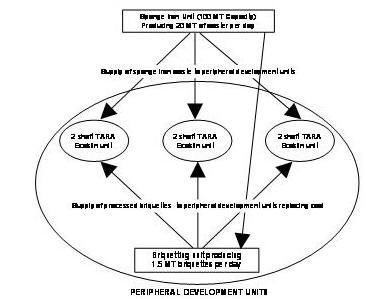

The brick setting in kiln is kept on support bars at the bottom of the shaft. Unloading of bricks is done from the bottom of the shaft with use of a trolley. The trolley is lifted (using single screw mechanism) till the iron beams placed on the trolley touches the bottom of the brick setting and the weight of bricks is transferred on to the trolley. The freed support bars are taken out. The trolley is then lowered by one batch (equivalent to 4 layers of bricks) – support bars are again put in place through the holes provided in the brick setting for the purpose. With slight downward movement, the weight of the brick setting is transferred to support bars. The trolley (with one batch of fired bricks on it) is further lowered till it touches ground level and then pulled out of the kiln on a pair of rails provided for the purpose. Every 2 - 3 hours, one batch of fired bricks is unloaded at the bottom and a batch of fresh green bricks is loaded at the top simultaneously. At any given time, there are typically 11 to 12 batches in the kiln depending on the green brick quality. Two chimneys located diagonally opposite to each other in the shaft remove fuel gases from the kiln. A lid is also provided on the shaft top which is kept closed during normal operation. Fuel gases are directed to pass through chimney thus not polluting working area on kiln top. The provision of shaft lid, better ventilation of working area on kiln top and higher and bigger chimneys are some of the highlights of VSBK kiln and its related process. The heating cycle for the green bricks is raw material specific (pre-heating, vitrification and cooling down) and is normally completed in 24-30 hours. A batch of bricks is loaded and unloaded every 2-3 hours; requiring round the clock operations and supervision. This requires special skills and the firing operator needs to maintain a correct balance between: n Energy - Controlled by amount of coal feeding n Airflow - Controlled by stacking density and damper position n Unloading speed - Controlled by the operator Benefits of waste utilization in TARA EcoKiln The TARA EcoKiln is an inherently fast firing process. Unlike conventional firing process of BTK’s or clamps, where the firing time is measured in days (14-21 days), the TARA EcoKiln firing process is completed within 24 – 36 hours. Thus the time for uniform heat distribution within the green brick is short. To ensure uniform heat distribution within the entire cross section of the mass, there is a need to provide heat from within the green brick also apart from the external heat given. This heat distribution within the green brick is achieved through “internal fuel”. Internal fuels are generally medium calorific value materials (1000 – 2000 KCal/kg) mixed with the soil during the green brick formation process. The various types of internal fuels recommended for use in the TARA EcoKiln are generally waste materials e.g. boiler ash, sponge iron waste, bottom ash from thermal power plants, rice husk ash and other carbon bearing wastes. Advantages of using waste materials as internal fuel: n Reduction in external coal consumption, thereby saving natural resources. n Uniform quality of fired material, in terms of ring, colour and strength. n Lower levels of pollution thereby reducing emissions and savings in green house gases. n Utilization of waste materials in a profitable manner thereby reducing soil consumption and preventing solid waste pollution. Experiences in Orissa In Orissa, four TARA EcoKilns were established in the year 2005. Two units in Rayagada, one in Muniguda and one in Pipili near Puri. All the kilns consist of a two shaft unit built and operated in a commercial mode. After initial reservations on utilization of waste materials, entrepreneurs were convinced to use the same after demonstrating trial results and quality. From existing experiences of TARA EcoKiln operation it is evident that use of industrial wastes e.g. boiler ash, sponge iron waste can bring about huge savings in external coal consumption. From the experiences in Orissa, the savings in external coal consumption vary from 11 to 24 tonnes per lakh of fired bricks. The art of controlling quality is in the mixing process. The better and more uniform the mixing process, the more consistent is the quality and resultant external coal savings. See map for different locations of TARA EcoKiln and their successful experiences in waste utilization. Principal findings Development Alternatives has tested various sponge iron waste from Chattisgarh and Jharkhand. Most of them gave a calorific value of between 2500-3000 KCal/kg. Depending upon the quality of soils various compositions have been made and recommended for use upto 10% by weight replacing soil. Dried green bricks were fired in the TARA EcoKiln at the VSBK Service Centre, Datia, Madhya Pradesh to simulate the actual production process. Fired bricks were tested for shrinkage, density, water absorption and compressive strength. Physical measurements e.g. ring in the fired bricks and colour was also observed. These parameters have considerable practical significance from the brick producer’s point of view. The strength of the fired bricks was found to be at par with the quality obtained in existing kilns. Results with respect to other parameters indicated considerable improvements over burnt bricks currently found in the market; especially with mechanized mixing and benchmark moulding practices. Plan of Implementation Depending upon the quality of the soil, sponge iron waste can be added upto a maximum of 10% by weight. Considering a brick size (10 in x 5 in x 3 in) a brick weight is around 4.5 kg. Thus approximately 4-5 MT (Metric Tonnes) of sponge iron waste will be used per day in each 2 shaft EcoKiln unit. Thus for a 100 MT capacity Sponge Iron Unit, only three TARA EcoKilns of two shafts each will be sufficient to use all the waste material produced. This type and quantity of waste material produced will also require some external fuel - coal. The approximate quantity required per day for each unit will be around 400-600 kg per day. The coal can also be replaced by making briquettes with the rest available sponge iron waste. Thus through the development of a group of three TARA EcoKiln and 1 briquetting unit the problem of total utilization of sponge iron waste can be solved. This will not only benefit the waste producers, but help the development of the peripheral region through promotion of energy and environment friendly technologies and making available valuable quality of infrastructural materials. q

Dr. Soumen Maity

|

The

EcoKiln works as a counter-current heat exchanger, with heat transfer

taking place between the air moving up (continuous flow) and bricks

moving down (intermittent movement). Green bricks are loaded in batches

from kiln top. Bricks move down the shaft through brick pre-heating,

firing and cooling zones and are unloaded from bottom. The combustion of

coal (added along with bricks at the top) takes place in the middle of

the shaft. Combustion air enters shaft from bottom, gets preheated by

hot fired bricks in the lower portion of the shaft before reaching the

combustion zone. Hot combustion gases preheat green bricks in upper

portion of the shaft before exiting from the kiln through shaft or

chimney.

The

EcoKiln works as a counter-current heat exchanger, with heat transfer

taking place between the air moving up (continuous flow) and bricks

moving down (intermittent movement). Green bricks are loaded in batches

from kiln top. Bricks move down the shaft through brick pre-heating,

firing and cooling zones and are unloaded from bottom. The combustion of

coal (added along with bricks at the top) takes place in the middle of

the shaft. Combustion air enters shaft from bottom, gets preheated by

hot fired bricks in the lower portion of the shaft before reaching the

combustion zone. Hot combustion gases preheat green bricks in upper

portion of the shaft before exiting from the kiln through shaft or

chimney.