|

Development

of the Indian handmade paper industry :

a case study

Dr. Arun Kumar and T N Subramanian

|

The

demand for paper and board in India will certainly continue to grow as the

country’s economy develops over the coming decades. The current per capita

consumption has risen from 2.5 kg (in 1994) to 4 kg. This figure is still rather

low compared with consumption per capita in many industrialized countries. Total

production of paper and board in India is predicted to rise in the next two

years from 3 million to 4 million tonnes.

Like other industries, paper production requires an assured supply of raw

materials. Given the current pressure on forests, the wood-based resources

traditionally used will become increasingly scarce and uneconomical. Their

scarcity has already led to a decline in capacity utilization in the Indian

paper industry. Paper and board mills are currently running at 60 per cent

capacity. In recent years, 0.86 million tonnes of installed capacity has become

redundant for various reasons including energy shortages and increasingly strict

pollution control legislation.

Handmade paper units, on the other hand, are mainly constrained only by limited

demand. In a world where the emphasis is clearly shifting to

environment-friendly products and production systems, the large untapped

potential of the handmade paper industry cannot be ignored. For a developing

country like India, faced with increasing shortages of natural raw materials,

energy sources and capital, the development of this industry offers considerable

potential to meet development objectives and respond to demand for both domestic

and export products.

Untapped Potential

Handmade paper units are defined essentially by the fact that their

operations are carried out manually. With

pure cellulosic (or raw) materials to be pulped, mechanical rather than chemical

pulping methods would be used. In fact, the existing handmade paper industry

relies wholly on secondary resources. There is no theoretical limit to the size

of handmade paper units, though in India they are often limited in practice to a

production capacity of 300 tonnes per year.

The handmade paper industry uses exclusively non-forest raw materials. At

present, it uses only cellulose-rich materials such as cotton rags, waste paper

and waste kraft. This could easily be extended to the use of biomass materials

and agricultural residues, some of which can be grown; specifically for handmade

paper production. Non-wood biomass resources have the additional advantage of

being amenable to conversion by environment-friendly processes. Some steps have

already been initiated in this direction for the utilization of straws, rice

husk and grasses.

Handmade paper production also offers extensive possibilities for in-plant

recycling. The paper waste emanating from industries incorporating intensive use

of paper can very conveniently be recycled for reuse in the parent industry,

often saving costs. Moreover, opportunities exist for interfacing paper

recycling systems with a host of industries involved in, for example, packaging,

printing, and industrial filter manufacture. In its effort to develop effective

systems for small-scale paper production, Development Alternatives has analysed

the performance of the Indian paper industry on all scales. This analysis has

drawn on industry publications and information concerning technology, trade and

production obtained directly from operating units.

The Indian paper industry can be divided into

four categories:

ii) large-scale (integrated) units - 50,000 tones and up per year;

ii) medium-scale units - 10,000 to 50,000 tonnes per year;

iii) small-scale agro-based units - up to 10,000 tonnes per year; and

iv) handmade paper units - 60 to 300 tonnes per year.

Our analysis indicates that specific consumption of resources is lowest in

handmade paper units. Water consumption per tone of paper is 150 cubic meters for handmade paper, compared with some 250 cubic metres for paper from

large-scale integrated units. Large-scale integrated units also consume large

quantities of electricity and chemicals, and are polluting. Small-scale

agro-based units are severely polluting, as they are usually unable to afford

pollution control equipment.

Large-scale units consume an average of 2.5 tonnes of forest-based raw materials

per tonne of paper; small-scale units consume an average of 3.5 tonnes of raw

materials, mostly agro-based, per tonne of paper. In contrast, a handmade paper

unit uses only 1.1 tonne of raw materials per tonne of paper produced. One

important reason for this is that waste generated in the manufacturing process

is internally recycled without any loss in quality.

Handmade paper production does not require large-scale capital investment.

Economically, this is one of its biggest advantages in the Indian context. It is

clear from Figure 1 (on the next page) that capital intensity increases

dramatically as the scale of production increases. For large-scale integrated

units, it can cost up to US$ 1000 to add each extra tonne of capacity. Adding

capacity in handmade paper units costs only

about half as much. Handmade paper enjoys a similar advantage in employment

generating potential. Employment creation in a handmade paper unit requires only

one tenth the capital required in a large-scale integrated unit (Figure 2). |

Figure 1

Installed capacity (tonnes/year)

|

Case study: the TARA handmade paper production unit

TARA (Technology and Action for Rural Advancement) is the

technology-marketing wing of Development Alternatives. The strategy of the TARA

handmade paper production unit of Development Alternatives is based on:

i) identification of unique market segments;

ii) development of a complete technology package, including recycling, for

handmade paper.

The TARA handmade paper unit was commissioned in 1991 in the peri-urban area of

Delhi. It employs 35 women and seven men. The key functions of paper

manufacturing are performed by women. The women operators have been given

on-the-job training. Productivity in the unit has increased from one to 4.5

tonnes per month, operating with eight-hour shifts.

Encouraged by the economic success of this enterprise, TARA is setting up a 16

tonne per month unit at Jhansi, in Central India.

Marketing Strategy

Handmade paper production in India has been constrained by poor demand,

which in turn has been limited because of poor marketing. Efforts by the

Government and its main village industry agency, KVIC, to promote the handmade

paper industry have focused on production of office stationery articles and the

creation of domestic demand. This emphasis on domestic markets has led to the

production primarily of paper and paper products which can, in fact, be

manufactured more efficiently and economically by large paper mills. This has

made the handmade paper industry appear uncompetitive.

This need not be the case. Handmade paper has its own unique selling

propositions (USP), and TARA has demonstrated the possibility of increasing the

production capacity through technology development. Only when market niches are

properly designed, however, can handmade paper become an economically viable

product.

|

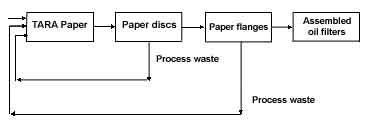

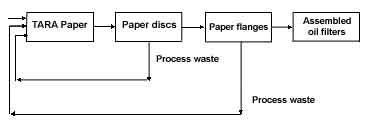

The handmade paper unit commenced production by committing a major share of its

output to industrial users. TARA was able to develop a high-quality black filter

paper for India’s leading automotive filter manufacturer. The aim was to

produce a chemical-free paper which had the correct strength characteristics to

replace the aluminium end discs of the filter. Other automotive filter

manufacturers catering to the replacement market have followed suit. TARA was

also able to develop a high-quality, zero-netwaste recycling system in which all

the waste generated during the manufacture of sub-components is recycled. The

flow chart and details of the recycling system are shown in Figure-3 . |

Figure 3

Recycling system for manufacture of automative filters

|

More recently, TARA has developed over 100 varieties of handmade paper using a

wide choice of waste paper, rags, natural biomass mixtures, and agro-residues.

Process development

Due to the flexibility of its manufacturing process, the TARA unit is able

to devise the blend of materials and recipes for manufacturing handmade paper

according to client needs and specifications. Through this exercise, a large

selection of papers of natural grades and shades (i.e. produced without chemical

bleaching) has been developed using a variety of biomass materials such as

straws, grasses and silk cotton. This has

been achieved with the minimum use of chemicals and through mechanical pulping.

Each variety of paper is specified according to the process parameters to be

controlled, which include pulp characteristics, colour matching, texture

control, and control of surface finish.

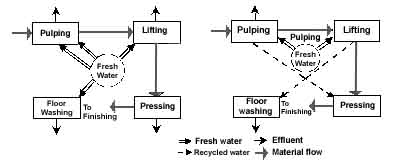

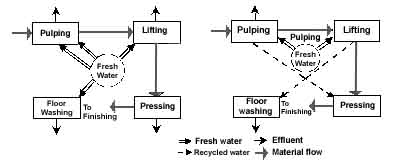

Another important aspect of process development is the internal recycling of

resources, especially water. In a proposed scheme (Figure 4 on the next

page), water from intermediate processes such as pressing will be

collected and reused in other operations. The targeted consumption of water in

proposed TARA units is 90 cubic metres per tonne of paper produced, compared

with the existing level of 150 cubic metres.

The standard equipment available for handmade paper production was found to be

inadequate, both in terms of performance and reliability. The equipment

development undertaken by Development Alternatives has resulted in higher

productivity. |

Figure 4

Waste utilization scheme for TARA paper unit

|

Handmade paper will gain widespread acceptance only if it can be

produced and delivered with a high level of consistency of quality and

reproducibility between different lots. Quality control is an even bigger

problem for the handmade sector than for the rest of the paper industry. Quality

control procedures have largely been ignored, leading to poor realization and a

very high level of rejection. The quality control procedure evolved by TARA lay

down specifications for the purchase of raw materials, inspection procedures,

and control of pulp parameters. Acceptance procedures for pulp can ensure that

the paper produced will be suitable for downline processes up to the finishing

stage.

Future areas of research

The handmade paper industry can flourish by adding new capacity, by

rejuvenation of existing units through technology inputs, and by development of

specific market segments. However, the sustained growth of handmade paper units

will require further research in several key areas:

Handmade paper production currently hinges on the availability of cotton rags

and waste paper. Many other materials

currently used only for blending could form a major component in the manufacture

of paper. Materials identified for active research are silk cotton (a type of

tree cotton), banana fibre, straws and grasses. These materials can easily be

cultivated locally for paper production.

The use of diverse materials will depend on the development of

environment-friendly processes. One area of research will be the use of

biotechnology, for example for the recovery of alpha cellulose from different

non-forest based materials, and for lignin removal using organisms like

white-rot fungi. The use of chemicals, and associated effluent disposal

problems, could be avoided through the use of biotechnological processes for

digestion.

Another area of research is the recovery of natural dyes for paper and printing

inks. The use of natural dyes can increase the choice of colours, textures and

finishes, besides leading to the creation of jobs involving, for example, block

printing.

Skill development

Handmade paper production requires close controls on thickness and

weight, both of which have traditionally depended on exceptional operator

skills. Technology development will need to integrate methods for rapid skill

development as a means of internal quality control.

Recycling partnerships

There is a large, unexplored wealth of waste cellulosic materials and

paper waste emanating from different industries:

Although systems exist for the recovery and recycling of major wastes, higher

value addition can be achieved by internal recycling in the industries

generating the waste.

This will require the creation of partnerships for integrating recycling

technology with social objectives in an economically viable manner. Such

partnerships need to be researched, and their wide-scale acceptance amongst

existing industries promoted.

Innovative production systems

Handmade paper production is amenable to decentralization. Through

research, units based exclusively on local production of non-forest based raw

materials can be planned. Future small, decentralized units can easily be

installed in rural areas, even areas with limited access to water and

electricity. The part of the production system that requires major capital

investments, and may thus benefit from economies of scale, could be based in

urban areas and integrated with the marketing system.

Conclusions

The case study of the TARA handmade paper unit demonstrates the importance

of technology development in tandem with the development of markets. Such

efforts have a potential to be widely replicated in a sustainable manner in

decentralized production units. Further research is needed in key areas such as

technology (including that required for recycling), the training of employees,

and marketing.

Source: UNEP Industry and Environment

References

1. See N.I. Rao, Quarterly

journal of Indian Pulp and Paper Association, 1993, pp. 1-11.

2. See R.S. Gora, K.L. Shah and P.K. Chakravarty, Quarterly Journal of

lndian Pulp and Paper Association Vol. 3 (4), 1393, pp. 44-49