|

Firing Innovation: VSBK

Technology

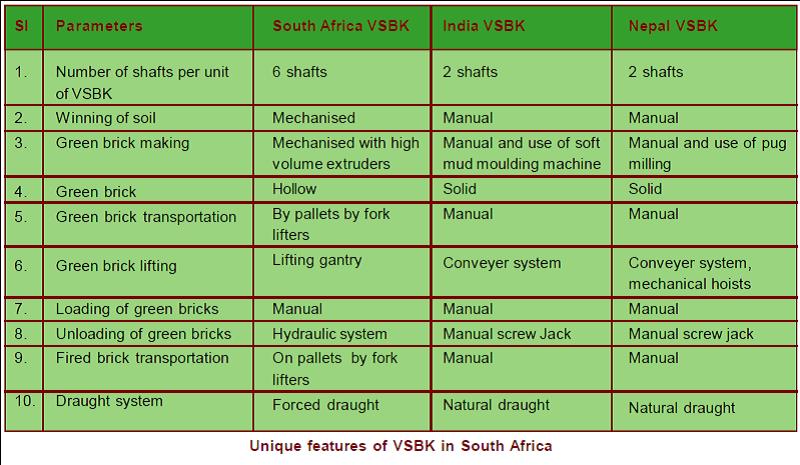

T This aspect of mechanisation is incorporated in the design of VSBK. The following features have been incorporated in the South African VSBK at Langkloof Bricks. The Swiss Agency for Development and Cooperation (SDC) has been instrumental in supporting the technology transfer of VSBK from India and Nepal to South Africa. The VSBK in South Africa is being implemented by a joint consortium of Skat, and Swiss Contact, Switzerland. Technical knowledge transfer and support is being provided through a VSBK global pool consisting of expertise from Switzerland, Nepal and India. The first pilot kiln in South Africa is being implemented at Langkloof Bricks, Humansdorp.

VSBK at Humansdorp was started

on the August 17, 2011. It is a six shaft unit with fully mechanised

system of lifting of green bricks to the loading platform, unloading of

fired batches through hydraulically operated systems and forced draught

mechanism for exhaust of gases. A single gantry system lifts and

supplies green bricks to all the shafts. Conveyer belt is also installed

to cater to green bricks requirement during operation in cases of

emergency. Out of the above, the most important and unique features of the South African VSBK were the hydraulic unloading system, induced draught and hollow green bricks. The hydraulic unloading system has a capacity of lifting 25 tonnes. Hydraulics of the shafts are connected to a single pressure tank. Speed of the piston can be controlled. During operation it takes around five minutes to unload one batch compared to 30 minutes during manual screw jack operation. Moreover, it has been observed that breakage is also reduced in hydraulic unloading compared to manual means. This is possible due to precise control of unloading speed in the mechanised system. The most important advantage of using hydraulic unloading, however, is the savings of operating labour. Normally it takes around six persons to operate six shafts per shift in manual unloading only, while the mechanised process uses one person for the same. In any brick firing system energy consumption is substantially reduced if the green bricks are dry and contain less mass. This is true for the VSBK technology too. The green bricks used in VSBK in South Africa are hollow and have a moisture content of less than 2 per cent by weight. This is made possible due to forced drying of the green bricks in a mechanical dryer. Initial operation of the kiln has showed encouraging results producing acceptable fired products of plaster brick quality as per South African standards. During the stabilisation period a specific energy consumption (SEC) of around 0.8 MJ/kg of fired bricks has also been achieved. With increased time and stabilised operation the SEC is expected to improve further proving the continued energy efficiency of VSBK. q Dr. Soumen Maity

|