| Compressed Biogas

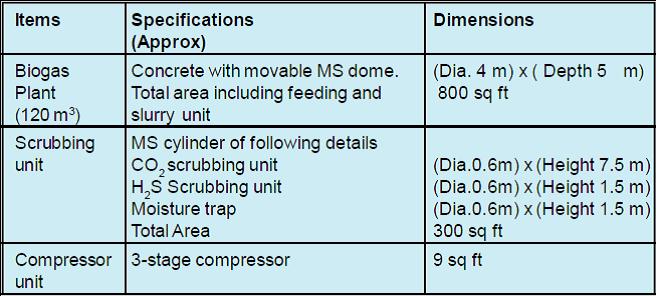

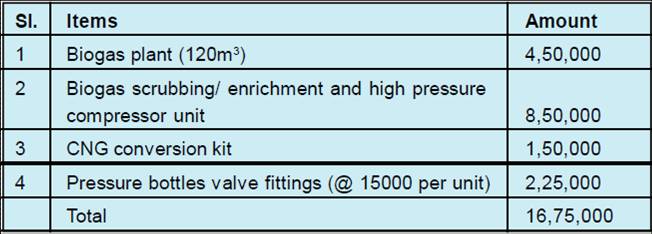

Introduction Due to the increasing energy consumption and dwindling fossil fuel reserves, the importance of biomass-based decentralised fuel such as biogas and biomass-based power generation has increased greatly. Biogas is a well-established renewable and environment-friendly fuel that delivers sustainable energy to rural communities. It also helps us in the reduction of Green House Gases such as methane, CO2, etc., to a great extent by replacing the fossil fuel or non-sustainable harvested biomass. Biogas is ideally suited for rural applications where the required animal or human excreta and agricultural waste are available in plenty. Harnessing such a resource promotes rural industries, agriculture, dairy and animal farming in a sustainable manner. Biogas is an environment friendly, clean, cheap and versatile fuel. It is produced by anaerobic digestion of degradable wastes such as cattle dung, vegetable wastes, sheep and poultry droppings, municipal solid waste, sewage water, landfill, etc. Presently, it is mainly used for cooking and lighting purposes in rural areas. Its utilisation is also feasible in automobiles or for transportation purposes by enriching and compressing it in cylinders. Biogas can be converted into BioCng after enrichment and bottling. It becomes just like another ordinary available Compressed Natural Gas used for running vehicles. Potential of the Technology So far, biogas has mostly been used as fuel for cooking. However, its potential has not been fully utilised yet. There is a great enhancement in its utilisation potential, particularly where bigger plants are in operation, e.g., institutional biogas plants in Gaushalas, dairy farms or community biogas plants in villages. Gaushalas are running generally on the basis of charity and most of them are not in a sound financial position. Enrichment and bottling of biogas will help to improve the situation to an appreciable extent. India has the highest domestic animal population of 489 million, out of which 185 million are cattle (milch and non-milch), as per the 2003 census. The acetogenic bacteria constitute the second group and are responsible for breaking down the products of the acidification step in order to form acetates. In addition, hydrogen and carbon dioxide are also produced during acetogenesis. Methanogenesis In this process, the methanogenic bacteria convert acetate or carbon dioxide and hydrogen in to methane. Biogas Composition, Properties and Utilisation as CNG Biogas comprises of 60-65 per cent methane, 35-40 per cent carbon dioxide, 0.5-1.0 per cent hydrogen sulfide and water vapour. It is almost 20 per cent lighter than air. Like Liquefied Petroleum Gas (LPG), it cannot be converted to liquid state under normal temperatures. Removing carbon dioxide and compressing it into cylinders makes it easily usable for various thermal applications. Compressed Biogas or CBG is nearly same as CNG (except CV value), can be used for all applications for which CNG are used. Biogas Enrichment Process A variety of processes are available for enrichment, i.e., removing CO2, H2S and water vapour. Commonly, CO2 removal processes also removes H2S. One of the easiest and cheapest methods involved is the use of pressurised water as an absorbent liquid. In this method, biogas is pressurised and fed to the bottom of a scrubber column where water is sprayed from the top. In the counter-currently operated absorption process, the carbon dioxide and hydrogen sulfide present in the biogas are absorbed in down going water and the methane rises and is collected in vessel. However, water requirement in this process is high but it is the simplest method of removing impurities from biogas. The other method of purification of biogas is a chemical treatment which removes CO2, H2S and moisture by various chemical reactions. Carbon Dioxide Scrubber CO2 is removed by reacting the Biogas with Sodium Hydroxide (NaOH) which converts carbon dioxide into sodium bi carbonate. Hydrogen Sulphide Scrubber When iron oxide reacts with Hydrogen Sulphide present in the biogas it forms iron sulphide thereby removing it Silica Absorber The moisture content of Biogas is absorbed through silica, thus removing all the water vapour present in the biogas which makes it suitable for bottling the Biogas. Concept of Alternative CBG (Compressed Biogas) Biogas contains a large proportion (about 40 per cent by volume) of carbon dioxide, a heavier and non-combustible gas and some fraction of hydrogen sulphide. Hence, biogas needs to be enriched by removing these undesirable gases to save compression energy and space in bottle and cut down corroding effect, which can be done by scrubbing. The scrubbing system is found to enrich methane by about 95 per cent or more, depending upon biogas inlet and water injection pressure. Biogas can be used for all applications designed for natural gas, assuming sufficient purification. Scope of the Technology Enriched biogas is made moisture free by passing it through filters, after which it is compressed up to 200 bar pressure using a three-stage gas compressor. Compressed gas is stored in high pressure steel cylinders as used for CNG. Besides cooking (in both domestic sector as well as hotels), there is large potential of this technology in buses, tractors, cars, auto rickshaws, irrigation pump sets and in rural industries. This will help to meet our energy demand to reduce burden on LPG/CNG to boost up energy security and will also improve economic status by creating employment generation in rural areas. Business Model A sample calculation is made from experience of Kanpur Gaushala, where cylinders are filled from an installed 120m3 biogas plant. This bottling plant fills 5 cylinders of 12 kg capacity per day. The market value is approximately Rs. 1500 per day or Rs. 45,000 per month. The process requires 3 tonnes of dung from 300 adult cattle per day, considering 40 per cent dung collection, i.e., 10 kg dung per cattle per day. Any commercial dairy can easily collect 20 to 25 kg dung per stall fed cattle. Thus, the whole investment can be recovered within two-three years through sale of CBG only. qSoumen Maity

(Endnotes)

|