|

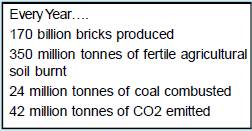

Green Building Materials for a Cleaner Environment Introduction C onstruction sector is one of the fastest growing sectors in the country with an annual growth rate of 9%, contributing to 8% of the GDP. Within the construction industry, brick production occupies a large share. Brick sector is the single largest source of air pollution and also exerts high pressure on natural resources like soil and coal. The sector also contributes to around 22% of total CO2 emissions in India. It is the second highest consumer of coal at 12.6% of the national demand. Competing soil resource use with agriculture also impacts food security.Increasing housing and infrastructure needs, rising energy prices, competing resource use, labour shortages and poor working conditions necessitate urgent action. Adoption of energy efficient measures (50% savings in fuel consumption through efficient technologies) can contribute to savings of 100 million tonnes of CO2e/year by 2020. Challenges and Potential Brick sector has a huge potential for GHG mitigation through adoption of clean production systems for emission reduction and improving energy and resource efficiency by industrial waste utilisation and process modifications. Government of India in November 2009 announced to voluntarily reduce its emission intensity by 20-25% on a purely domestic level between 2005 and 2020. Technologies like the Vertical Shaft Brick Kiln (VSBK), Zig Zag Kilns, fly ash bricks, hollow bricks etc. can greatly aid in the voluntary reduction announced. Although technology options exist, evidence of adoption of cleaner technologies and practices is lacking due to cumbersome regulatory procedures of applying for land and accessing finance; inadequate information, incentives and consumer demand for cleaner, low carbon construction material. Moreover regulation is not strictly enforced by state agencies due to shortage of manpower and knowledge on appropriate technology and legislation. The challenge is to integrate technology-policy measures to achieve the twin objectives of augmenting supply while lowering carbon emissions. Another challenge is implementing favourable market and non market incentives to accelerate the uptake of clean production over conventional energy and resource intensive systems. The key stakeholders in the policy processes are government departments like Industries, Environment, Mining and Public Works and regulatory authorities like the Central and State Pollution Control Boards. Another set of important stakeholders are technology service providers and financial institutes private and public banks and state departments like MSME, KVIC who offer subsidies and incentives. Policy Imperative Increasing international pressure on cleaner environment and steep increase in coal prices are the key drivers facilitating energy saving techniques for brick production. Some policy recommendations to increase uptake are:. Inclusion of eco-friendly building material in State Industrial Promotion Policy to enable access to incentives and subsidies States like Orissa and Chhattisgarh have included fly ash bricks in their priority sector. This entitles the units to avail fiscal benefits. This needs to be extended to all cleaner brick production technologies across the country. Inclusion of eco-friendly building material in PWD schedule of rates (SoR) at state and national level at prices comparable to conventional building material Inclusion in SoR allows for tendering with eco-friendly building material. The Delhi SoR includes fly ash, hollow bricks. Issuance of procurement guidelines mandating use of Eco materials in public construction projects will enable large scale uptake of such products. Encouragement of cleaner brick production technology adoption through preferential policy regime for pollution NOC, citing and mining. Current regulations are independent of technology though certain technologies have environmental, energy and resource advantages over conventional ones. The Ministry of Environment and Forests has notified separate emission norms for VSBKs. Similarly there is a need to introduce a preferential policy regime for pollution control, soil mining and citing for cleaner brick production technologies.The potential for adopting Clean and Low Carbon options by the Indian Brick Sector can be potentially accelerated through enabling policy incentives. Enabling finances and large scale awareness programmes will also create interest amongst the small scale brick makers. q Kriti Nagrath References: UNDP Green Bricks (2009) - http://www.undp.org.in/sites/default/files/climate_pdf/11.pdf www.ecobrick.in Construction industry development council, India 2006-07 Reddy, Venkatarama BV and Jagadish, KS (2003) Embodied energy of common and alternative building materials and technologies. In: Energy and Buildings, 35 (2). Brick by Brick: The Herculean task of cleaning up the Asian brick industry by Urs Heierli and Sameer Maithel, 2008

|