|

HOW

TO

MAKE

BUILDING

FOR

GOOD

SEISMIC

PERFORMANCE? |

Construction Materials

|

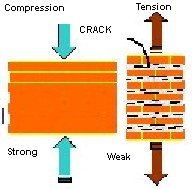

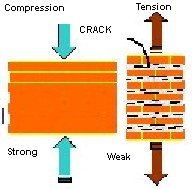

In India, most non-urban buildings are made in masonry. In the

plains, masonry is generally made of burnt clay bricksand cement

mortar. However, in hilly areas, stone masonry with mud mortar

is more prevalent; but, in recent times, it is being replaced

with cement mortar. Masonry can carry loads that cause

compression (i.e., pressing together), but can hardly

take load that causes tension (i.e., pulling

apart) (Figure 1).

Concrete is another material that has been populary used in

building construction particulary over the last four

decades.Cement concrete is made of crushed stone

pieces (called

aggregate), sand, cement and water mixed in appropriate

proportions. Concrete is much stronger than masonry under

compressive loads, but again its behaviour in tension is

poor. The properties of concrete critically depend on the amount

of water used in making concrete; too much and too little water,

both can cause havoc. In general, both masonry and concrete are

brittle, and fail suddenly.

Steel is used in masonry and concrete building as reinforcement

bars of diameter and ranging from 6mm to 40 mm. |

|

|

Figure 2: Masonry is strong in compression

but weak in tension. |

Reinforcing steel can

carry both tensile and compressive loads. Moreover, steel is a

ductile material. This important property of ductility enables

steel bars to undergo large elongation before breaking.

Concrete is used in buildings along with steel reinforcement

bars. This composite material is called reinforced cement

concrete or simply reinforced concrete (RC). The amount

and location of steel in a member should be such that the failure of

the member is by steel reaching its strength in tension before

concrete reaches its strength in compression. This type of failure

is ductile failure, and hence is preferred over a failure

where concrete fails first in compression. Therefore, contrary to

common thinking, providing too much steel in RC buildings can be

harmful even!!

|

Capacity Design Concept

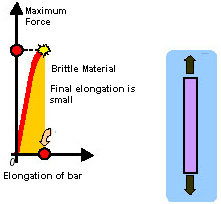

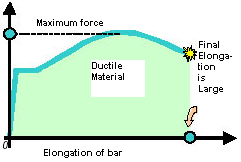

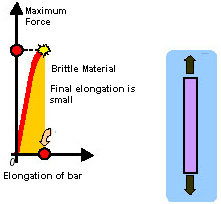

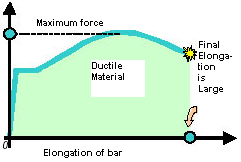

Let us take two bars of same length and cross-sectional area -

one made of a ductile material and another of a brittle

material. Now, pull these two bars until they break!! You will

notice that the ductile bar elongates by a large amount before

it breaks, while the brittle bar breaks suddenly on reaching its

maximum strength at a relatively small elongation (Figure

2).Amongst the materials used in building construction, steel is

ductile, while masonry and concrete are brittle .

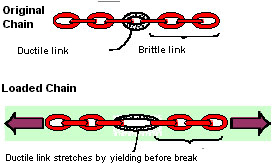

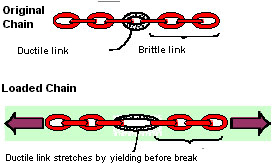

Now, let us make a chain with links made

of brittle and ductile materials (Figure 3). Each

of these links will fail just like the bars shown in Figure 2.

Now, hold the last link at either end of the chain and apply a

force F. Since the same force F is being

transferred through all the links, the force in each link is the

same, i.e., F. As more and more force is applied,

eventually the chain will break when the weakest link in

it breaks. If the ductile link is the weak one (i.e.,

its capacity to take load is less), then the chain will show

large final elongation. Instead, if the brittle link is the weak

one, then the chain will fail suddenly and show small final

elongation. Therefore, if we want to have such a ductile

chain, we have to make the ductile link to be the weakest

link.

|

|

| |

Figure 2:Tension

Test on Materials – ductile versus brittle materials. |

|

Let us take

two bars of same length and cross-sectional area - one made of a

ductile material and another of a brittle material. Now, pull

these two bars until they break!! You will notice that the

ductile bar elongates by a large amount before it breaks, while

the brittle bar breaks suddenly on reaching its maximum strength

at a relatively small elongation (Figure 2).Amongst the

materials used in building construction, steel is ductile,

while masonry and concrete are brittle .

Now, let us make a chain with links made

of brittle and ductile materials (Figure 3). Each

of these links will fail just like the bars shown in Figure 2.

Now, hold the last link at either end of the chain and apply a

force F. Since the same force F is being

transferred through all the links, the force in each link is the

same, i.e., F. As more and more force is applied,

eventually the chain will break when the weakest link in

it breaks. If the ductile link is the weak one (i.e.,

its capacity to take load is less), then the chain will show

large final elongation. Instead, if the brittle link is the weak

one, then the chain will fail suddenly and show small final

elongation. Therefore, if we want to have such a ductile

chain, we have to make the ductile link to be the weakest

link. |

Figure 3: Ductile chain design |

|

Earthquake-Resistant Design of Buildings

Buildings should be

designed like the ductile chain. For example, consider the

common urban residential apartment construction - the

multi-storey building made of reinforced concrete. It consists

of horizontal and vertical members, namely beams and

columns. The seismic inertia forces generated at its floor

levels are transferred through the various beams and

columns to the ground. The correct building components need

to be made ductile. The failure of a column can affect the

stability of the whole building, but the failure of a beam

causes localized effect. Therefore, it is better to make

beams to be the ductile weak links than columns. This

method of designing RC buildings is called the strong-column

weak-beam design method (Figure 4). |

|

|

Figure

4: Reinforced Concrete Building Design:

the beams

must be the weakest links and not the columns – this can be

achieved by appropriately sizing the members and providing

correct amount of steel reinforcement in them. |

Quality Control in Construction

The capacity design concept in earthquake

resistant design of buildings will fail if the strengths of the

brittle links fall below their minimum assured values. The strength

of brittle construction materials, like masonry and concrete, is

highly sensitive to the quality of construction materials,

workmanship, supervision, and construction methods. Similarly,

special care is needed in construction to ensure that the elements

meant to be ductile are indeed provided with features that give

adequate ductility. Thus, strict adherence to prescribed standards

of construction materials and construction processes is essential in

assuring an earthquake-resistant building. Regular testing of

construction materials at qualified laboratories (at site or away),

periodic training of workmen at professional training houses, and

on-site evaluation of the technical work are elements of good

quality control.

Resource Material

Paulay,T., and Priestley,M.J.N., (1992),

Seismic Design of Reinforced Concrete Buildings and Masonry,

John Wiley, USA.

Mazzolani,F.M., and Piluso,V., (1996), Theory and Design of

Seismic-Resistant Steel Frames , E&FN Spon, UK.

Authored by:

C.V.R.

Murty

Indian Institute of Technology Kanpur, Kanpur, India

Sponsored by:

Building

Materials and Technology Promotion Council, New Delhi.

Suggestions/comments may be sent to

eqtips@iitk.ac.in

To see previous

IITK-BMTPC Earthquake Tips, visit

www.nicee.org

Back to Contents

|