|

India,

like many other developing countries, is facing an acute energy

crisis. This crisis has two major implications.

On one hand, a majority of people living in rural areas still

depends on fuel wood and other biomass resources for meeting the

cooking energy needs. Forests are declining rapidly because of their

multiple use for industrial purposes and the population pressure on

land. Depletion of forest resources has caused a significant rise in

serious environmental problems, culminating in soil erosion and loss

of biological diversity.

On the other hand, India has been forced to overexploit its fossil

energy resources to meet the increasing demand for commercial

energy. For example, large-scale exploitation of coal adds to

greenhouse emissions, overall pollution and the resultant global

warming.

The energy crisis faced by India and other developing countries

could only be solved through the utilisation of alternate energy

resources. The potential for Renewable Energy resources is

tremendous. These resources include hydropower, solar energy, wind

energy, and bio-fuels. Unfortunately in India, these resources are

classified as non-commercial fuels that include wood, biomass, cow

dung and biogas. At present, over 90 percent of rural households

depend on these resources for their energy needs.

Biomass Energy

Potential

Globally, the solar energy input globally is 12000 times greater

than today’s commercial energy supply. Further, the world wide

photosynthesis activity is estimated to store 17 times as much

energy as it consumes. Unlike fossil fuels that take millions of

years to form, biomass is a truly renewable resource with plant life

renewing itself every year. Biomass energy has a bright future as a

sustainable energy resource.

Biomass is basically organic matter produced by plants through the

process of photosynthesis. It mainly contains cellulose,

hemicellulose and lignin; with an average composition of C6H10O5

and its variation, depending upon the nature of the biomass. Biomass

combustion is CO2 neutral and the biomass energy does not

contribute to GHG emissions.

In rural areas, the energy used for cooking stems mainly from

firewood, cattle dung cakes and agricultural residues/forest

residues. There is, however, an increasing trend towards utilizing

coal, kerosene and LPG since households prefer a clean and reliable

fuel. India produces over at least 200 million tonnes of

agricultural residues per annum that, in terms of energy, is

equivalent to nearly 100 million tonnes of coal. If we add the

forestry wastes and the wild weeds, the increase in biomass would be

significantly greater. Utilization of these residues can meet most

of our household requirements for cooking and heating purposes.

Direct burning of wood or biomass is highly inefficient as hardly

10% of useful energy is actually utilized. The emissions contain

toxic volatiles that are injurious to health (especially to lungs

and eyes). Incomplete combustion adds Carbon Monoxide gas, which is

poisonous and pollutes the atmosphere. A safer, convenient and far

more efficient method is to convert the agriculture/ forestry waste

into a smokeless briquetted fuel. Most biomass materials (such as

leaves, twigs, land/water weeds, rice husk, rice stalk, cotton

stalk, bagasse, pine needles, saw dust, groundnut shells, mustard

husk, soyabeen waste, seed pods, coffee/tea waste, coconut shell and

pith, coir waste, fruit waste, foliage, small wood chips) could be

converted into briquetted fuel. While powdery biomass materials such

as rice husk, mustard husk, groundnut shells and saw dust could be

directly converted into biomass briquettes; other woody materials

could be easily converted to charcoal briquetted fuel. (The specific

heat of some of the locally available biomass is provided in Table

1 at the bottom of the page.)

|

|

|

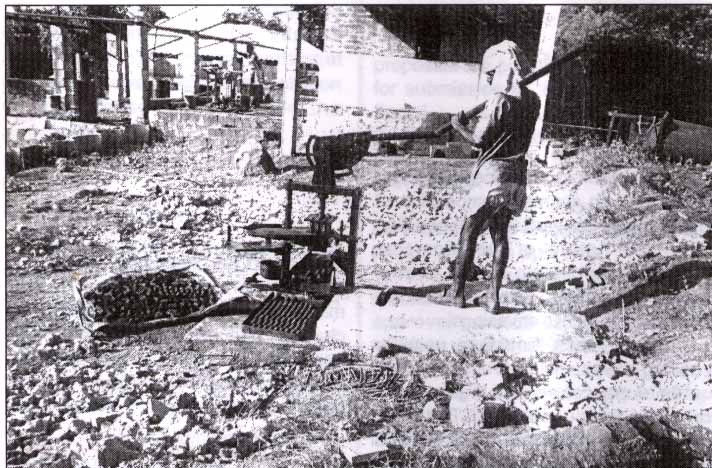

Production

of Charcoal Briquettes at TARAgram, Orchha |

Income

Generation Opportunities

Charcoal

briquetting fuel manufacture could be run as a successful micro

enterprise. A family or a group of persons could easily run this

unit as a sustainable livelihood venture.

The Process

Charcoal

Briquetting involves the conversion of biomass waste into a cleaner

fuel through the process of Charcoal Production, followed by

Briquette Production.

Charcoal

Production

In this

process, thee persons are engaged for supplying char. For the first

two days, each person harvests the biomass. On the third day, one

drum is provided to each of the three persons for chopping and

firing the biomass. The daily average yield of char (after firing)

per drum is 30 kgs. Hence, a total yield of 90 kgs per day. As the

three persons are engaged at a daily wage of 50 rupees per day, they

earn a total of 150 rupees per day to produce a total of 90 kgs of

char. This amounts to an average of two rupees per kg, including the

transportation cost.

|

Table

- 1 |

|

Specific

Heat Values of Locally Available Biomass |

| Biomass |

Energy

Value

(Kcal/Kg) |

Charcoal

Value

(Kcal/Kg) |

| Laltana

Camara |

3771 |

6700 |

| Ipoemia |

3700 |

6600 |

| Mulberry

Stems |

3750 |

6650 |

| Wood

Barks |

3800 |

6750 |

| Congress

Grass |

3900 |

6700 |

| Kardhai |

4300 |

7100 |

| Parthenium |

3800 |

6600 |

| Butia

Monosperma |

3900 |

6800 |

Briquette Production

A

proportionate mixture of char, clay and cow dung is grind in a

grinding machine with a capacity of 70 kg per hour. Two persons are

required to operate the briquetting machine to produce as much as

600 kg of briquettes per day.

Two activities are involved in making the wet briquettes. This

engages 3 person days, resulting in a total production of 600 Kg

briquettes per day. Considering the salary of each person at Rs.1100

per month, amounting to a total of Rs.3300 per month, the labour

cost could be calculated by dividing this figure with 15000 kg

briquettes produced monthly. This gives the average cost of 22 paise

per Kg on site, excluding transportation.

|

Table

- 2 |

| Briquetting

Cost (per tonne) |

| Charcoal

cost |

Rs.

2000/- |

| Labour

cost |

Rs.

220/- |

| Binder

cost |

Rs.

150/- |

| Electricity

cost |

Rs.

100/- |

| Capital

invested |

Rs.

300/- |

| Production

cost of briquetted fuel |

Rs.

2770 |

The production cost of one tonne of briquette fuel amounts to a

total of 2770 rupees. (See Table 2). This means that the production

of 1 kg of charcoal briquette is even less than three rupees (i.e.

Rs.2.77).

Conclusion

This surely

proves that charcoal briquetting is not only a technologically

feasible but also an economically viable proposal. This project has

certain unique and interesting features as it is based on renewable

resources that have no conflict in terms of their usage. The project

is not sensitive to the cost of inputs and is based on very high

inputs of manpower. The benefits can accrue to the marginalised and

landless families engaged in the production of char.

It is very significant to note that in this enterprise, the material

cost is nil and all conversion costs are actually earnings, which

depicts that charcoal briquetting is a truly unique sustainable

livelihood venture. q

For

further enquiries, contact

Rajesh Bajpai (Energy

Unit)

Development Alternatives,

1077 Civil Lines, Jhansi – 284001

Tel :

(0517) 330892, Fax

: (0517)

440557

E-mail :

energy_raj@yahoo.com

|