| TARA : Technology with a Human Face | ||||||||||||||

|

|

||||||||||||||

|

The Vision It is with this vision of innovating and introducing people-oriented technologies that a Delhi-based organisation TARA or Technology for Action for Rural Development came to the fore in the early eighties. TARA is a technology promotion wing of Development Alternatives. It is an attempt to evolve an egalitarian development paradigm, which is socially just and in harmony with nature, through the widespread dissemination of appropriate technologies. E F Schumacher, the world-famous author of the book ‘Small Is Beautiful’, unfolded that the appropriate technologies are generally small in scale, decentralised in character and people-friendly in nature. They minimise waste, pollution and the use of non-renewable resources. It is vital to empower the local rural people with such technologies that could be converted into sustainable livelihoods.

Sustainable Livelihoods Sustainable

livelihood creation basically translates into the creation of

livelihoods that empower individuals to earn enough money to provide

for basic amenities such as food, clothing and shelter, without

destroying the natural resource base. It also enables people to lead

a life of dignity in a In simple terms, creating sustainable livelihoods is the only path leading to the ultimate goal of sustainable development. In order to be sustainable, the development process has to be equitable, efficient, ecological and empowering. And, in the Indian context, self-employment is the best route to true empowerment of the marginalized and neglected - especially women and the rural poor. Similar is the case of the urban poor who form 48 to 50 percent of any metropolis, living in shanty towns or slums. Converting Technologies into Trades Development Alternatives plans to create millions of jobs by establishing micro-enterprises through its commercial wing — TARA. The main aim of TARA is to demonstrate the economic viability and feasibility of Development Alternatives’ innovations to provide work and dignity to the rural and urban poor of India. The entire TARA venture is driven by an urge to convert appropriate technologies into sustainable trades and useful, marketable products. The basic premise of making these TARA products is that all of them are designed to maximise benefits to the community and local economy and to minimise damages to the environment and resource base. The sustainable enterprises promoting the TARA technologies are basically small, decentralised, and utilise renewable local resources. The Beginning The very first product to emerge out of the TARA assembly line was an improved wood cookstove. This cookstove, termed the TARA Shakti Chulha, was low on fuel-consumption and also low on smoke-emissions in the kitchen. Studies reveal that the conventional cookstove or Chulha emits so much smoke that one hour in that smoke-filled kitchen is like smoking ten packets of cigarettes at a time. The smokeless TARA Chulha checked this health hazard and reduced the drudgery of rural women who traversed several kilometres each day to procure just a few twigs of firewood. Thus, this improved cookstove design prevented deforestation to a great degree and also brought down the passive smoking of millions of housewives. Tens of thousands of TARA Shakti Chulhas have been sold and several more copied by local manufacturers all across the subcontinent as well as abroad. This was the very first venture of TARA and a successful one at that. Development Alternatives and TARA have come a long way from those days of early eighties and have a basketful of innovations today. Appropriate Technologies Though the TARA technologies cover the whole range of the rheostat, some of the prominent ones are: TARA Tile Maker

TARA Balram Mud Block Press

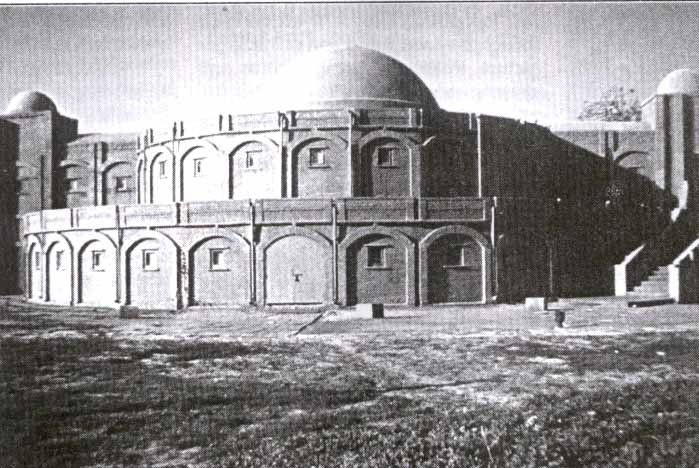

Vertical Shaft Brick Technology This technology is a boon for the conventional brick makers who are still using the age-old technology of piling crude clay bricks in a heap and burning them with a non-renewable energy resource like coal. The VSBK technology provides the best quality bricks with the least energy consumption due to its efficient design. The Vertical Shaft Brick Kiln comprises one or more shafts which are loaded at the top with sun-dried mud bricks for firing purposes .The firing zone is in the middle. The fired bricks are cooled by the draught of air moving up from below. They are lowered down with the help of a trolley which is moved out to unload the bricks from the bottom of the kiln. There is no wastage of heat in VSBK, hence it is a highly energy-efficient technology. Thus, VSBK has a positive impact on forests, climate change and the local air-quality. Ferrocement Roofing Channels

TARA Concrete Block Making Machine

Wealth from Waste One such interesting technology is the hand-made paper technology. All the paper used in our offices for writing and printing purposes or the umpteen number of books one reads or the note books one writes upon, actually, is created by cutting down huge forests. And, deforestation means more air-pollution, more greenhouse gases and depletion of the ozone cover protecting our plant earth. So, why not use recycled paper that is made out of paper waste, cotton rags and other cellulose waste? We can easily turn these rags into riches by using a mini paper-recycling plant. In fact, students of the Delhi based Bal Bharti Air Force School are using one such ‘baby’ paper plant to publish their in-house journal. The process is literally a child’s play and is extremely safe as there are no chemicals involved in the entire paper-making process. The cotton waste is dumped in a tub or ‘vat’ full of water. After sometime it disintegrates into pulp that is later lifted with the help of a sieve and dried to give a nice sheet of paper. This recycled paper is already being used for making lamp shades, gift boxes, carry bags, lap top boxes, files, letter pads, diaries and conference bags. Friends of the Earth Vermi-composting and natural composting are two wonderful technologies which serve humanity and conserve nature. Composting, basically, is the biological reduction of organic wastes to humus. Whenever a plant dies, its remains are attacked by soil micro-organisms and are reduced to an earth-like substance that is beneficial for the growth of the plant roots. Such natural composting is an integral part of the wheel of life. All you have to do is to make a pit in your garden at home or school and dump in all the dried leaves or the garden waste. You can decompose the waste by alternatively layering the pit with the waste and soil. This will generate a natural compost or fertiliser that could be used in the school garden. This organic manure could also be sold to students, their parents or in neighbourhoods and the funds could be utilised for nature club activities. Vermi-composting is yet another process to convert biodegradable waste into rich humus by using earthworms. In simple terms, this method utilises earthworms to turn your kitchen waste into a nitrogen-rich manure. It is nothing short of a miracle that once the worm gulps down your kitchen waste, the ingested matter undergoes chemical changes to give out a rich plant food. All schools have their own canteens and they could adopt this technology. Vermi-composting technology not only solves the problem of solid waste to the extent of giving rich compost in return, it also helps students realise the importance of small creatures like earthworms and helps them shed their fear. Actually, you have to simply separate the earthworms from the compost, once it is ready, and keep on adding more kitchen waste into the earthworm pit. This way you neither harm the creature nor damage the environment since you are not using any chemical fertilisers. Weaving Magic Carpets The TARA Handloom technology has reduced the drudgery of traditional weavers, especially women, by improvising the conventional loom. The TARA Loom has upgraded the traditional loom by introducing advanced features like the flying-shuttle which weaves more cloth with the same effort. Apart from features like the fly-wheel and steel frame for higher efficiency, it has introduced a ‘take-up’ mechanism for semi-automatic operation and a ‘let-off’ mechanism for automatic tension control. Thus, it has proved to be a technology which is simple to operate, has a high productivity and gives a superior quality fabric than the traditional loom. So, TARA has achieved a breakthrough in the handloom technology by inventing a loom that is as efficient as a powerloom and still does not need any electricity. A new generation weaving machine that combines versatility with the ease of operation, TARA Loom is ergonomically designed to conform to the traditional workmanship for producing more and better quality fabrics. TARA textiles have an unusually uniform weave and represent the best synthesis of powerloom and traditional fabrics. Elegant designs by master weavers in both ethnic and contemporary designs, are now in vogue everywhere. Murky Waters As research reveals, 44 millions people are currently affected by water quality problems. These problems stem either from pollution, or the prevalence of fluoride, arsenic or iron deposits or the ingress of saline water. There is an urgent need for understanding the gravity of the situation in terms of water quality and to ensure its appropriate management and sustainable usage. Currently, there are a number of Delhi schools involved in a campaign called CLEAN or Community Led Environment Action Network and are monitoring as well as reporting the quality of water in the different zones of the Capital. Development Alternatives is constantly working towards alternatives which create a harmony between brother man and mother nature. So, it has designed kits (under the CLEAN campaign) to monitor the quality of the water we drink and the air we breathe. These kits indicate whether the level of pollution is within the prescribed safety limits or not. Jal TARA and Pawan TARA are portable kits designed to test water and air pollution, respectively. The Jal TARA kit can test 14 parameters of drinking water and river water quality to ensure whether the water is fit for consumption or not. It checks biological pathogens like the Coliform Bacteria, which spreads water-borne diseases like gastro-enteritis, dysentery and diarrhoea. Apart from checking physical parameters like the pH and turbidity, it also checks the presence of chemical hazards like fluorides, chlorides, residual chlorine, iron, phosphate and ammonia. The Pawan TARA kit is so simple that the quality of air could be checked even by small kids. It checks three parameters, namely - Respirable Particulate Matter, Sulphur dioxide and Oxides of nitrogen. This kit has proved to be more efficient than other brands of commercially available low volume air sampling kits in the market. Development Alternatives provides the after-sale service for both the kits, apart from the supply of refill chemicals, accessories as well as training. Apart from manufacturing eco-friendly technologies and products, TARA also provides consultancy services, training and feasibility project reports. It undertakes turnkey projects of land and water-management, low cost constructions, renewable energy power plants and income-generating enterprises. Electricity from Biomass DESI Power is a TARA affiliate which has been set up to deliver electricity to far-flung rural communities which are not connected to the national power grid. The electricity, in this case, is produced from renewable biomass (like Ipomea) and agricultural waste. The gasifier turns the biomass into a gas through the process of pyrolysis and the gas, then, is used to produce electricity in diesel generators. The cost of electricity generated by this process is much lower than that produced by diesel generator sets and is even competitive with the grid supply, if available. Small is Possible If we adopt even some of these pragmatic technologies and implement them in our neighbourhood, the world can be a better place to live in. Our combined micro efforts as citizens could bring about macro changes in the present scenario. After all, tiny little drops do make a mighty ocean. If we all join hands, we can certainly prove that small is not simply beautiful but possible as well. q |

||||||||||||||

| Back to contents |