|

Low Carbon Cement – A Green Alternative for a Clean Future T he uncontrolled release of greenhouse gases such as carbon dioxide ( CO2)

into our earth’s atmosphere has resulted in an average temperature rise

of 0.85°C over the last hundred years1.

Cement industry is one of the major sources of anthropogenic CO2

released. CO2)

into our earth’s atmosphere has resulted in an average temperature rise

of 0.85°C over the last hundred years1.

Cement industry is one of the major sources of anthropogenic CO2

released.

Low Carbon Cement - A Research Initiative Materials Research Group of the Indian Institute of

Technology, Delhi has been actively engaged in the development of Low

Carbon Cement (LCC) which results in a lower carbon footprint as

compared to Ordinary Portland Cement (OPC) currently in use. In addition

to being eco-friendly, LCC improves the desirable properties of concrete

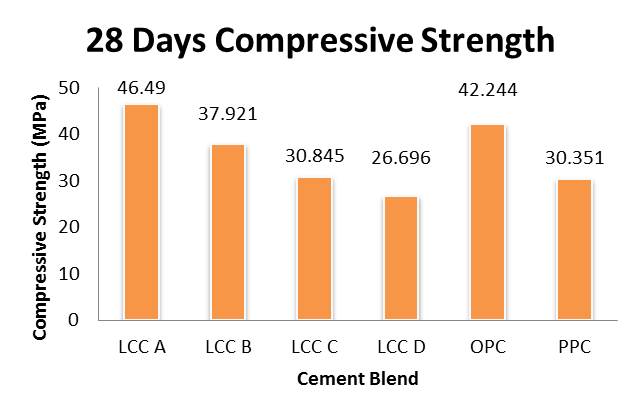

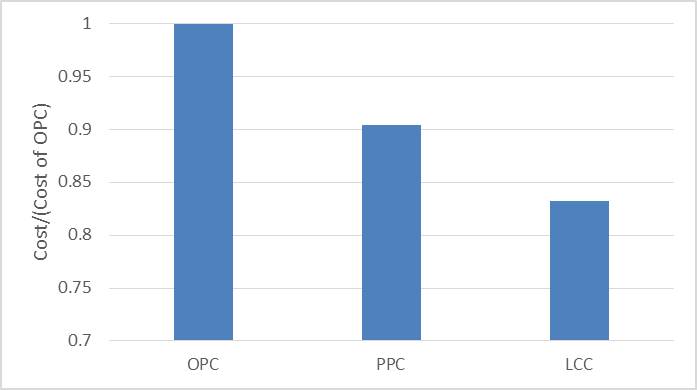

such as strength, durability etc when compared to OPC. In association with Development Alternatives, a new type of Low Carbon Cement (LCC) in which 50% of the cement has been replaced using a mix of calcined clay and limestone has been developed. Indian clay that contains kaolinite (also known as china clay) can be turned into a reactive pozzolanic material (metakaolin) on heating it up to 800°C. This process is known as the calcination of clay. The calcined clay has been inter-ground with limestone and clinker to produce four different cement blends. These cement blends are under various stages of testing in the laboratory and the field. The initial test results appear to be very promising. The economic analysis of production costs of Ordinary

Portland Cement (OPC), Portland Pozzolana Cement (PPC) and Low Carbon

Cement (LCC) show that up to 19% reduction in the cost is possible by

using LCC instead of OPC which can translate into major savings for

cement companies. One of the major advantages of LCC over PPC is the

high levels of clinker replacement possible using LCC. With the current

clinker factor of 0.5, it is possible to obtain 5% more savings using

LCC as compared to PPC with 30% fly ash replacement.

Way Forward Further research on Low Carbon Cements such as understanding the effect of variation of raw material composition and further lowering of clinker factor on cement properties is planned. Various long term durability issues such as carbonation, corrosion etc are being studied. A building is being constructed using LCC entirely to study the field performance of the structure. Meetings with various stakeholders such as BIS, NCCBM and various cement companies are being organised in order to standardise and to engineer the cements as per the needs of the industry. Easy availability and abundance of clay throughout our country ensures that production of LCC requires no additional infrastructure investment by cement companies. Calcination of clay can be carried out using the existing rotary kilns that are present in all the cement plants. With the cement demand set to double by 2020 2 ,using low carbon alternatives such as LCC in place of OPC has become vital to ensure a clean, bright future for our country. qShashank Bishnoi Endnotes 1 IPCC (2013). Summary for Policymakers. In: Climate Change 2013: The Physical Science Basis. Contribution of Working Group I to the Fifth Assessment Report of the Intergovernmental Panel on Climate Change [Stocker, T.F., D. Qin, G.-K. Plattner, M. Tignor, S.K. Allen, J. Boschung, A. Nauels, Y. Xia, V. Bex and P.M. Midgley (eds.)]. Cambridge University Press, Cambridge, United Kingdom and New York, NY, USA. 2 IEA and WBCSD (2013). Technology Roadmap: Low Carbon Technology for the Indian Cement Industry. |