|

Biomass-based Power Generation for Rural Livelihoods

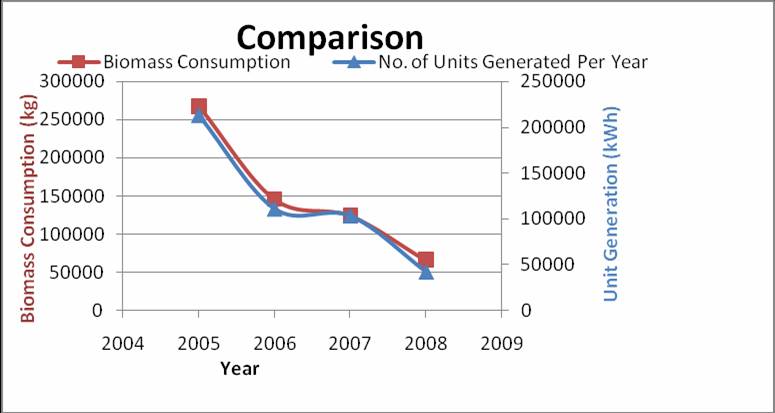

I ndia, a rapidly developing economy, requires colossal inputs of energy - especially electrical - to fuel its development projects. Rural areas of India provide immense untapped opportunities to bring about economic as well as social upliftment of rural society. Since independence, however, centralised power has not been able to provide adequate amounts of electricity required for the economic growth of the rural areas, home to a majority of the Indian population. The possibilities of decentralised energy generation systems in Indian villages were assessed in the light of this situation and the concept of Independent Rural Power Producers (IRPP) was evolved to take advantage of the amended government policies and legal framework for the power sectors. IRPPs - based on local sources of renewable energy – can, under today’s conditions, pose a stiff competition to the power supplied from conventional fossil fuel power plants at point end use.DESI Power, Orchha Decentralised Energy Systems India (DESI Power), a sister concern of Development Alternatives (DA), is a private, no profit-to-the-promoters company whose mission is to build decentralised energy systems in rural areas on a large-scale commercial basis to meet the local energy needs and promote the creation of substantial local livelihoods. The first DESI Power Plant was commissioned at Orchha in 1996 in TARAgram, the Technology Demonstration Centre of DA. The technology of gasification plant was developed by the Indian Institute of Science (IISc). The plant has been running successfully for the last 13 years as a commercial unit and serves the various enterprises located in TARAgram such as the paper making unit, MCR tiles unit, general lighting, etc. Technology and Gas Generation Process  The process of gas generation starts with loading of the reactor with biomass till it is full. The water pumps fill the water seal of the reactor. The blower is switched on to suck oxygen from the reactor so that biomass combustion takes place in partial supply of oxygen (Pyrolysis). Firing is initiated at the bottom of the reactor through a nozzle and gas is generated after about thirty minutes (Oxidation followed by Reduction). The gas (at 900° C) is passed through a double stage cooler, which brings the temperature down to 5° C below ambient temperature. The sequence of coarse and fine sand filter - through which the gas is passed - then removes the carbon particles and other impurities from the gas. This mixture (CO, H2, CO2, CH4, and N2), known as producer gas, is fed to the dual fuel engines which then drive the generator. Modification for 100% Gas Engine It was observed that the gas obtained from the above purification process, when supplied to engines utilising 100% gas, left carbon residues on the walls of the engine. Hence, a chiller was installed after the fine sand filter for the gas was supplied to the gas engine so that the smaller carbon particles agglomerate to form bigger-sized units. This gas is then passed through porous iron candles covered with knitted long fibre filters where the carbon particles stick and the gas thus obtained is 95% pure with high calorific value. Technical Performance Over the Years The total number of units generated by the DESI Power Plant at Orchha is 11,96,320 kWh (measured on December 2008). A dual fuel engine was developed to utilise the gas. This required a mixture of 20% diesel with gas produced from the reactor. This process costs INR 4.24 to produce one unit using this engine, a significantly lower price than the cost incurred if pure diesel engine was used (INR 7.47/unit). The gas engine (which utilises 100% gas) was commissioned in December 2004. In the previous years, the plant had generated 6,65,120 kWh. Since commissioning, the plant has generated 4,69,834 kWh, significantly reducing the costs incurred due to diesel usage. Typical loads handled by the plant range between 300- 700kW per day. However, approximately 15 kW of power is used by the plant as auxiliary input. Running cost of the plant (exclusive of salaries) is 3.90INR/unit produced by the plant. This plant requires 2 skilled workers and 3 unskilled workers as the total workforce. However, only 3 workers are employed at present for operations. Types of Biomass used in DESI Power

Biomass Usage

Back to Contents |