|

Affordable Housing in the Context

of Sustainable Habitat

T he

EWS and LIG constitute more than 99 per cent share of total housing

shortage of 24.71 million in India (figures from Planning Commission

Report 2007). This number is further expected to increase to 26.5

million by 2012. This is due to the large number of people at the bottom

of the economic pyramid. The business viability of this sector has

already been established with market researches. The obvious logic here

is that such a large number of people, with limited amounts of cash put

together, have a considerable buying potential.

Building Industry

and Climate Change

The climate is changing. The earth is warming up, and there is now

overwhelming scientific consensus that this is human induced. With

global warming on the increase and species and their habitats on the

decrease, chances for ecosystems to adapt naturally are diminishing.

Climate change may be one of the greatest threats facing the planet.

The building and construction sector is a key contributor to the

phenomena of climate change. The built environment accounts for a large

share of energy use (with associated greenhouse gas emissions), waste

generation or use of natural resources. Areas of key concern also

include production of construction materials, use and recycling,

consumption of hazardous materials, integration of buildings with other

infrastructure and social systems, water use and discharge, etc. The

construction industry is estimated to be responsible for around 40 per

cent of the total carbon emissions globally. Buildings are responsible

for large shares of resource use and waste generation: approximately 40

per cent of materials use, 30 per cent of solid waste generation, and 20

per cent of water use. The materials and technologies used in buildings

also have a significant impact on their users’ health and well being.

Compared with many other industry sectors, the opportunities to reduce

emissions are easier to achieve and also more substantial. Energy use in

buildings can typically be reduced by 50 per cent or more using proven

and commercialised technologies and approaches. This sector has the

potential to lead the fight against climate change.

The huge volume of housing to be constructed, especially that in the

affordable sector can have a huge role in this direction towards

lowering carbon emissions. It has been seen that typically a house made

using appropriate technologies has the potential to reduce at least 25

per cent of energy input itself, which can prove to be a tipping point,

considering the scale of construction. With the Prime minister’s

National Action Plan on Climate Change having a sub-mission on

sustainable habitat, the issue takes a completely new dimension in the

Indian context.

The Model Eco

Village Housing

The village in question is Guru Nanak Dev Nagar, village Gaggar,

district Muktsar, Punjab. This project was conceived by the Punjab

Government to provide shelter to the BPL families of the village. The

project was started by Ambuja Cements Foundation in collaboration with

the GoP in 2008 and was completed in August 2009. In all, 129 houses

have been constructed with the cost of a single house being Rs 1.7 lakh,

at around Rs 470/sq ft. Each house with a covered living and cooking

area of 370 sq ft and a bath and toilet of 15 sq ft is built on a plot

of 1200 sq ft. A single house has two rooms, a kitchen and a bathing

area and toilet. Each plot has space for a cowshed and a cycle/scooter

shed and the possibility of vertical expansion with another floor that

may be added as the family size increases.

Technology

Description

The house has a conventional brick foundation. The walls are made using

fly ash bricks in rat trap/rowlock bond. The roof of the main built

volume is in precast plank and joists. This is then topped with a

weather proof course of brick tiles on mud phuska over bitumen PCC

screed. The roofing over verandah and the kitchen is done using Micro

Concrete Roofing (MCR) tiles with MS rafters and purlins. Local masons

were trained in the usage of these technologies by TARA Nirman Kendra

(TNK), a building centre of the Development Alternatives Group

specialising in green building materials and habitat design. This

training was conducted on a demonstration house at the site.

Roofing:

Pre-fabrication for Cost Savings

Incorporating pre-fabricated plank and joist roofing significantly

lowered the construction costs. Plank and joist roof with the three

layered weatherproof course have worked out to be 20 per cent cheaper

than conventional RCC roof. It took two days for roof construction,

including finishing the assembly of prefabricated components with screed

concrete, saving at least 10 man-days per house in addition to savings

on scaffolding and curing period of 21 days for each house, which

amounted to further construction efficiencies.

An existing local enterprise of fly-ash bricks, situated around 40 km

from the project site, was trained in the production and quality control

of planks and joists while MCR tiles were sourced from another small

entrepreneur in Chandigarh. The technology transfer was undertaken by

TNK. The casting and curing was done at the production facility with

strict quality checks.

Walling:

Utilisation of Industrial Waste

Waste fly ash generated by the GND thermal power plant at Bathinda was

used in making the fly ash bricks for wall construction. The bricks are

made using the FaL-G technology which uses a mix of fly-ash (50 per

cent), coarse sand (40per cent), lime and gypsum (together 10per cent)

and cement (less than 1per cent). The lime and gypsum are also waste

materials sourced from an oxygen plant and fertiliser plant

respectively.

The house

has load bearing 9" thick fly ash brick walls. Red bricks were used in

an interspersed manner (up to 10 per cent of the total bricks used in a

house) to provide relief from the otherwise grey colour of fly-ash

bricks and improve the aesthetic aspect of the house. Usage of Rat-trap

bond for wall masonry which incorporates a cavity within the 9" wall

thickness reduced the brick requirement by 20 per cent per cubic meter

of wall. This reduces the load of the superstructure on the foundation,

resulting in savings due to optimised foundation design as well.

Similarly, mortar requirement is reduced by 20 per cent (as compared to

conventional English Bond) for a 1:4 cement-sand mortar. Apart from

this, construction by trained masons ensures superior quality of

brickwork, obviating the need for cement plaster. The exposed brickwork

has led to 15 per cent of overall cost reduction. Locally made pre-cast

cement jaalis have been used to look out into the verandah. Doors and

windows were made using local mango wood.

Rainwater from each house is directed through drains to harvesting pits

located in the central parks of the settlement. Bathinda region receives

approximately 410 mm of rain annually. The water harvesting system

designed in the settlement is expected to catch 80 per cent of

precipitation on the site (approximately 10,000 cubic meters) both

through street drains as well as roof rainwater drains and direct these

for recharging the aquifers.

The toilets constructed by Sulabh International have the twin-pit

system, which uses each pit alternatively in a cycle of around three

years to percolate wastewater and, at the same time, decompose the

faecal matter into organic manure. Cost of a complete toilet, including

squatting pan, plumbing, finishes, etc., is approximately Rs 7,500.00.

Technology

vis-à-vis Sustainability

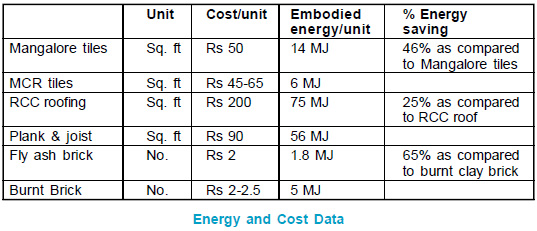

One of the key measures for ecological sustainability of building

technologies is embodied energy. Embodied energy represents the

non-renewable energy consumed in the extraction of raw materials, their

processing, conversion to building materials (manufacturing),

transportation to site and construction using the building material. Low

embodied energy of the material signifies that the net carbon emissions

during the production, transportation and construction of the building

element are also low. So the lower the embodied energy, the higher it

ranks in its ecological sustainability.

Pre-fabricated components generally have lower embodied energy in

comparison to the cast in situ elements due to both enhanced production

efficiency and reduced requirement of high energy raw materials.

The third aspect here is the usage of industrial waste like fly ash for

construction. The ecological advantages are twofold, it utilises an

industrial waste and prevents the usage of potentially fertile

agricultural land. Bricks are hydraulically compressed and not baked,

which eliminates both usage of burning fuel and the emissions associated

with it. Also, as the quality of the bricks is superior with controlled

dimensions, well formed edges and surfaces, it removes the need for

plastering, further reducing the embodied energy of the walling system.

Unbaked MCR tiles as a replacement for market standard, high energy

asbestos sheeting and Mangalore tiles can save up to 46 per cent energy.

Design and

Planning

Around 20 houses form a cluster around a central green open space. The

central movement spine links the two main access routes to the site. All

the roads are soft paved. Rainwater falling on the pavements is drained

into the green areas for percolation. Native trees and shrub species

were planted to create a wholesome environment.

Incremental Model

for the House Design

Each house has been designed to allow for future expansion. A flat roof

aids such an incremental approach and also optimises the first costs to

the investor, where only the minimum space requirements of the customer

are catered to and any future modification and customisation lies at the

discretion of the user.

Climatically

Responsive Design

The houses are designed to respond to the hot and dry climate of the

region. Openings are so designed so as to ensure cross ventilation and

adequate shading by chhajjas. Openings on the south side of the houses

are avoided. A weatherproof layer has been added on the top of each

house.

Optimal Sanitation

Systems

The sanitation system provided by Sulabh International under the total

sanitation mission uses water efficient pour flush toilets with twin-pit

leach pits. Adequate care is taken to ensure that leach-pits are at a

suitable distance from the water source – that is piped to the

settlement. Vernacular design features like aara (niche) in main

entrance wall and traditional brick parapet patterns were incorporated

in the house design to integrate it with the cultural psyche. The

intention was also to bring about a perception shift in the local

community, who associate low-cost housing with bland looking boxes.

Delivery Process

The Ghaggar eco-housing was a government-led project where land and

infrastructure were provided by government or quasi government agencies.

The land was provided by the Zila Panchayat, the plantation in the green

areas was undertaken by the forest department, water supply by the

public health department and the roads and park boundaries were set up

by the Punjab Mandi board. The government collaborated with the private

sector in this case ACF of Ambuja Cement Limited as part of its CSR

function facilitated its Foundation for financing and management of the

project. ACF hired TARA Nirman Kendra (TNK) of the Development

Alternatives Group as a technical consultant to the project. The

eco-housing was designed with affordability and sustainability as key

concerns. TNK trained the local masons and undertook the technology

transfer of appropriate technologies to a local entrepreneur to ensure

quality fly-ash bricks and prefabricated plank and joist roofing.

Individual plot holders, all in the BPL and landless category, were

identified by the local committee formed by the Panchayat. This

committee was guided by ACF during the implementation period.

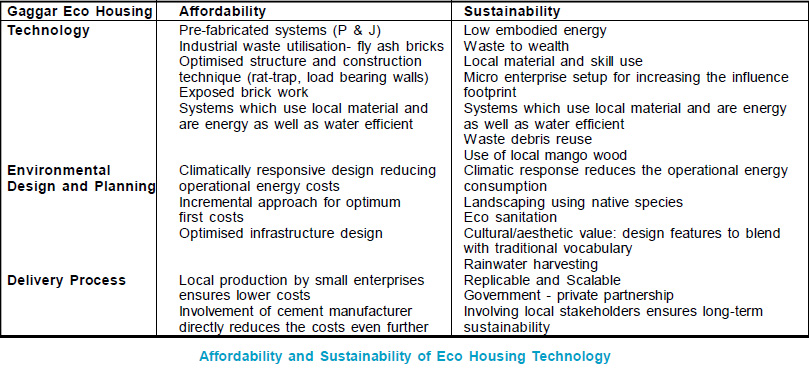

Lessons

The lessons are summarised in the framework where the interconnected

criteria of technology, environmental design and planning and delivery

processes are evaluated against the affordability and sustainability

parameters.

Criteria with

Affordability and Sustainability as Parameters

An approach of appropriate systems has affordability as the objective

and economic, social and environmental sustainability are the foundation

of habitat provision. It becomes even more important to have

sustainability as an underlying layer in all affordable housing

initiatives. This is because sustainable measures can not only reduce

the actual construction cost as well as post occupancy operational

costs, but also significantly help in reducing the now, almost certain,

(impending) economic offsets of climate change adaptation.

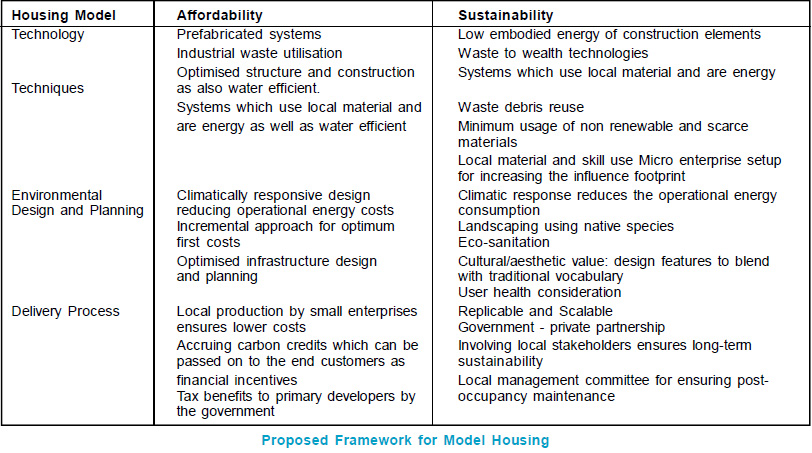

Delivery Mechanism

of Affordable and Sustainable Habitat

Affordable housing in the larger sustainable habitat framework implies a

three-pronged approach of social, economic and technological

interventions in the housing delivery mechanism. This is a complex

cyclical process with the policy level interventions forming the overall

guiding force. The three interconnected loops converge towards the

central objective of affordable and sustainable habitat, of which

housing is the most important module. Capacity building of local

enterprises is imperative to the process since it makes the model

replicable on a larger scale, resulting in even lower costs.

Conclusion

Affordability of housing should be reinterpreted in terms of its social,

economic and ecological costs and benefits. The built as well as natural

environments are integral to the economic capital of the habitat.

Environmental design and planning should take into account the climatic

response, waste and water management and eco-sanitation, contributing

towards pre- and post-occupancy affordability and sustainability. The

overall housing delivery mechanism should take into account the role of

different stakeholders and have social, economic and technological

measures for affordable housing in the larger context of sustainability.

q

Pankaj

Khanna

pkhanna@devalt.org

Akshay Goyal

agoyal@devalt.org

Back to Contents

|