|

New Business with TARA Fly

Ash Technologies Technology

and Action for Rural Advancement (TARA) actively promotes the TARA Fly

Ash technology in diverse scales of production with a variety of

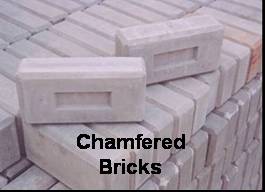

machines developed and markete TARAAS-1818; a fully mechanised Vibro-compaction machine with a production capacity of 8000 bricks/shift TARA Mechanised BALRAM; a hydraulically operated compaction machine with a production capacity of 4000 bricks/shift TARA BALRAM; a manual compaction machine with a production capacity of 1200 bricks/shiftFly ash is a very fine powdery material, predominantly silica, generated after combustion of finely ground coal in thermal power plants. Fly Ash bricks are made up of fly ash, sand and cement. Another popular variant is Fal-G bricks made with fly ash, lime, sand and gypsum. Recent government regulations have made it compulsory for use of fly ash based construction materials (bricks, cement etc) in an area of 100 km radius for thermal power plants. This has meant a great new business opportunity for fly ash brick manufacturers. To suit market requirements, the strength of the bricks can be engineered by varying the composition. The TARA BALRAM machines deploy hydraulic/manual compaction to produce a variety of fly ash blocks including bricks with chamfered edges. New Business Opportunities TARA has devised new business opportunities for fly ash brick manufacturing with different levels of capital investments to suit the needs of enterprises. The TARA AS-1818 and TARA BALRAM Mechanised packages are suited for urban markets with easy access to fly ash. New TARA enterprises have commenced operations in Bilaspur, Jabalpur, Jamshedpur and Dhanbad. The TARA BALRAM manual package is ideally suited for peri-urban and rural markets. This package has been extensively used for the reconstruction of houses in the tsunami affected areas at Karaikal. The detailed specifications of the TARA technology packages for fly ash bricks is given in the table below Chamfered Bricks Based on the raw material, fly ash bricks can be mainly grouped into two categories: FlyAsh bricks using cement as a binder Raw materials include: fly ash, cement and sand Fly Ash brick using lime as a binder Raw materials include: fly ash, lime gypsum and sand; also known as Fal-G.

Standard Bricks Size: 230mm X 108mm X 75mm Maximum tolerance :For length ±3mm; breadth and height ±2mmNew Achievements TARA provides complete technical know how and operational training to the valued customers at site. That is why we are able to deliver the quality products and services to the valued clients in different regions of the country. BALCO, Korba: Due to the shortage of land for disposal of fly ash and government pressure, BALCO started to get involved with the local youth to start the production of Fly Ash bricks, with assurance of raw materials, machines, and market support provided by BALCO. Mr R.K. Kher (Head of CSR) initially selected two groups from villages Rogbhary and Balgi Basti to start the Fly Ash bricks production unit in one village itself. BALCO initially took two manual machines (TARA BALRAM) to produce the Fly Ash bricks for both groups. After the supply of TARA machines the training programme was organised with both youth groups in June 2006. After the great success of both groups, BALCO, placed 18 TARA BALRAM machines order to TARA. Now the production capacity of the TARA machines supplied is 90 lakh bricks per year, creating 30000 man day jobs and will utilise 16-20 thousand tons Fly Ash waste annually.

NTPC, Korba started with two TARA BALRAMs to start the production of FaLG bricks. The commissioning of machines and technical training programme will start very soon. M/s A.A. Industries, Muri is going to start Fly Ash Bricks/pavers production very soon. The fly ash will be procured from the HINDALCO power plant. Production capacity is 30 lakh bricks annually. M/s Structural Venture, Jamshedpur (Ash source from TATA Power) Production capacity 30 lakh bricks annually M/s Shivam Industries, Lalitpur, U.P (Ash source from Parichha Power Plant) Production capacity 15 lacs brick annually M/s Gold Bricks, Jabalpur TARA Mechanised BALRAM machine assembled at Industrial area Rechhari, in Jabalpur. Mr N.P. Sukala owner of Gold Bricks has about 40 lacs chamfered bricks order from a Government Department. M/s Vandana Industries, Hazaribag Jharkhand (Fly Ash source from PTPS) Production capacity 30 lakh bricks annually q

Innovation Systems Branch

|

d

by TARA. The three machines are:

d

by TARA. The three machines are: