Biogas Plant- So Easy to Use!

The Biogas plant is designed to have very easy feeding with minimum labour input and mechanism to recover 100% treated slurry with its dewatering arrangement in a user friendly manner.

Mr. Hitesh Saha, owner of Reliable Dairy, Jabalpur, has been using the Flexi Biogas model for the last five months. He finds this 2m3 biogas plant economically attractive. A daily saving of about 1kg of LPG per day leads to a total saving of Rs 690 per month. Beside this, the sale of organic manure would further provide a source of income to the extent of Rs 360 per month - which he is yet to establish.

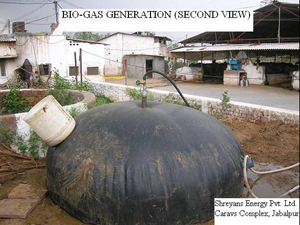

The Shreyans Energy Pvt. Ltd, Jabalpur, has developed this Flexi Biogas plant keeping as target customers, the farmers who are engaged in milking business in addition to agriculture to meet their cooking fuel requirement, This wood provide smoke free and healthy environment to their family members especially women who generally spend an average 5-6 hours each day in their smoky kitchen.

The Biogas plant is designed to have very easy feeding with minimum labour input and mechanism to recover 100% treated slurry with its dewatering arrangment in a user friendly manner .

Once the plant is commissioned and handed over to the user, they become dependent on this source of fuel supply and organic manure production system. The regular feeding of animal dung into the biogas plant ensure even control on flies and odour - which is otherwise unavoidable. In addition to energy and organic manure the biogas plant offers a systematic and scientific method of solid waste disposal.

So far, the only conventional biogas plant used in the country is the Deenbandhu model. The success of this plant depends entirely on the skill of the mason constructing this plant and the proper curing followed by the user.

Since it is constructed with brick masonry and plaster, the chances of leakages

are always there.The cycle time to construct this plant is minimum one month

whereas Flexi model could be installed in a day's time. In fact the entire

village could be covered in a couple of days.The flexi model is made at

the factory and tested pneumatically hence success rate is almost 100%.

Since it is constructed with brick masonry and plaster, the chances of leakages

are always there.The cycle time to construct this plant is minimum one month

whereas Flexi model could be installed in a day's time. In fact the entire

village could be covered in a couple of days.The flexi model is made at

the factory and tested pneumatically hence success rate is almost 100%.With the present rate of cement, labor and supervision charges, the cost of Deenbandhu model will in any case exceed the Flexi biogas plant of Rs 9900.

Livelihoods generation: After the successful field trial, five unemployed rural youth are being trained to promote this dream model. It is strongly believed a team of 5-6 people (1-2 entrepreneurs, 1 skilled technician and 3 helpers) per tehsil can sell this and ensure themselves a livelihood. A comprehensive training programme and suitable tool kits have been developed to make sure that this team can deliver quality service the customers.

A moderate target of 5000 plants has been fixed for the next financial year and the process of at least one CDM case by bundling a group of 3500 plants.