| Alternative Building Materials and

Technologies for Housing the EWS

Objective of the study

The objective of this paper will be to study various existing and new/innovative material and construction techniques that may be used for mass housing for EWS.

Need for the study

There is around 24.7 million-house shortage in India on an average. Most of the shortage (more than 90%) is for the economically weaker section (EWS) as per NBO and NHHP.

The percentage of any formal housing available for urban poor, such as EWS/ LIG/ resettlement housing NOT classified as a slum in Ahmedabad is 2.75 per cent. Percentage of the total housing stock, classified as slum by the AMC is 37 per cent. The percentage of the total housing stock classified as squatters, i.e. not recognisable as slums or legal tenements/settlements is 18 per cent. Required housing stock production capacity required to meet the housing need for urban poor is 12000 units/annum.

There is a growing concern that persisting shortage of cost-effective building materials for the vast majority of population is a serious impediment to improving the housing conditions of the people. While popular traditional materials are short in supply, high demand for them has resulted in their high prices and taking them out of the reach of the poor. Most of the new alternate materials are yet to be translated into marketable products for mass application. Excepting cement and steel, all other materials required for housing are likely to have constraints of supply.

Keeping the above aspects in view, the Government of India and State Governments have been promoting research in the fields, housing and construction activities. This has led to a number of new alternative building materials and techniques aimed at reducing the cost of house construction and improving the performance of conventional building materials and techniques.

In spite of this, big construction Departments/Agencies like CPWD, MES and State PWDs have yet to come forward in a big way to adopt these technologies. In order to provide impetus to adoption of low cost construction technology in the country, they should think in terms of providing some kind of incentive to the contractors who are often reluctant to undertake any construction employing innovative techniques.

Method of study

A case study of low-cost housing for EWS chosen in Ahmedabad (EWS housing scheme in Chandlodia). The construction materials and technology has been studied. The cost per dwelling is worked out. Cost per sq.m for different elements like foundation, walling etc. worked out.

Applications of various other materials available locally has been studied. Keeping the same number of dwellings and similar design.

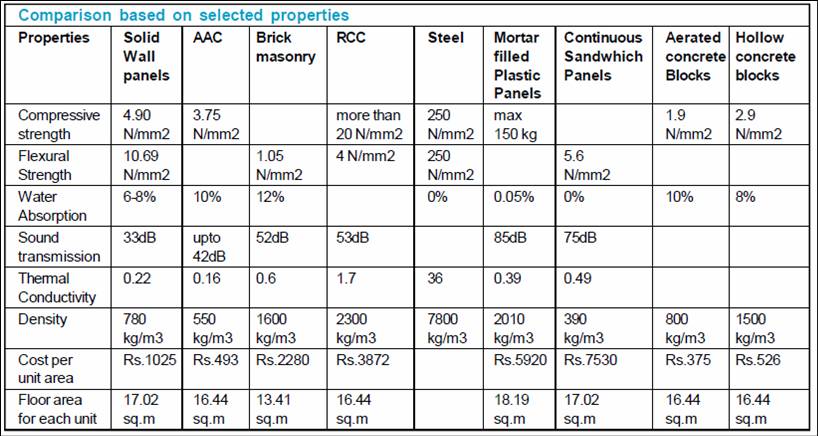

The material properties of all materials under consideration has been listed down. The cost per unit area of the material has been worked out. Comparison of the alternative material with existing materials on the basis of cost of construction and the properties like compressive strength, tensile strength, flexural strength, water absorption, sound transmission, thermal conductivity, density is done.

Suitable alternatives out of the systems  considered is proposed. considered is proposed.

Scope of study

The scope of study only includes housing for EWS. The same materials can be used for housing for other income groups as well by performing a similar analysis.

Materials which are available in and around Ahmedabad have been considered for the study.

The cost of the materials have been computed as in the city of Ahmedabad.

What is EWS affordable housing?

The family income of those classified as EWS is Rs.3300 or less. The cost of an affordable house permits repayment of home loans in monthly installments not exceeding 30-40 per cent of the monthly income of the buyer.

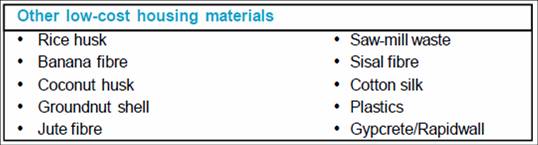

Materials promoted by BMTPC for use in low-cost housing

Sand Lime/Calcium silicate bricks

Burnt clay-Flyash Bricks

Pre-cast channel unit for floors and roofs

Precast RC planks and joists for floors and roofs

Thin RC ribbed slab for floors and roofs

Precast concrete waffle units for floors and roofs

Precast doubly curved shell units for floors/roofs

Precast reinforced prestressed concrete ribbed or cored slab units for floors/roofs

Reinforced brick and reinforced brick concrete slabs for floors/roofs

Prefabricated brick panels for floors/roofs

Ferrocement roofing channels

Precast concrete stone masonry blocks

Materials for use in western region of India

Instead of mud blocks for walling, stabilised clay blocks with cement/lime/bitumen shall be produced and used. Concrete blocks or stone blocks for masonry.

In areas where flyash is available, units production for producing building components utilising flyash for clay-flyash bricks or and flyash sand-lime bricks.

In place of R.R. masonry, solid concrete blocks of 30x20x15 cm and 30x15x15 cm with designed concrete mixes using 50 mm aggregates/stone spalls or hollow concrete blocks of 40x20x20 cm shall be used. The partition wall blocks shall be 30x10x10 cm solid or 40x20x10 cm hollow.

Criteria for selection of materials

The materials should be selected carefully depending on the use and the final product. For constructing an EWS housing scheme, the most important factor is cost. If the material comes under the cost bracket then the properties are checked according to which the final selection is made.

Important properties according to which materials have been compared:

Strength properties

Compressive Strength

Tensile Strength

Density

Modulus of rupture

Impact Energy

Fire safety

Fire Resistance

Surface Spread of flame

Fire penetration

Fire propagation

Thermal properties

Thermal Conduction

Thermal expansion

Acoustic properties

Sound Transmission

Water permeability

Water absorption

Water infiltration

Emission of odors

Vermin infestation

Resistance to wear

Abrasion resistance

Weathering

Freeze-thaw

Bactericidal

Transport

Storage on site

Handling during installation

Abrasion

Jointing materials

Adherence of sealants

Staining of sealants

Coatings

Ability to receive and retain coatings

EWS project in Chandlodia, Ahmedabad

Cost Structure per sq.m for building elements

Rs.2638 Construction cost for foundation per sq.m carpet area

Rs.3872 Construction cost for walling per sq.m carpet area

Rs.1785 construction cost for roofing/flooring per sq.m carpet area

Rs.1372 construction cost for finishing works per sq.m carpet area

Rs.662 construction cost for door/window per sq.m carpet area

Rs.10328 Total construction cost per sq.m carpet area

The cost of construction of one housing unit is Rs.169793.

The total cost of construction for foundation is Rs.43367 for one unit. This is 25.5 per cent of the total cost.

The total cost of construction for walling is Rs.63653 for one unit. This is 37.4 per cent of the total cost.

The total cost of construction for roofing/flooring is Rs.29338 for one unit. This is 17.3 per cent of the total cost.

The total cost of construction for finishing items is Rs.22549 for one unit. This is 13.3 per cent of the total cost.

The total cost of construction for door/window fixing is  Rs.10885 for one unit. This is 6.4 per centof the total cost. Rs.10885 for one unit. This is 6.4 per centof the total cost.

Conclusions

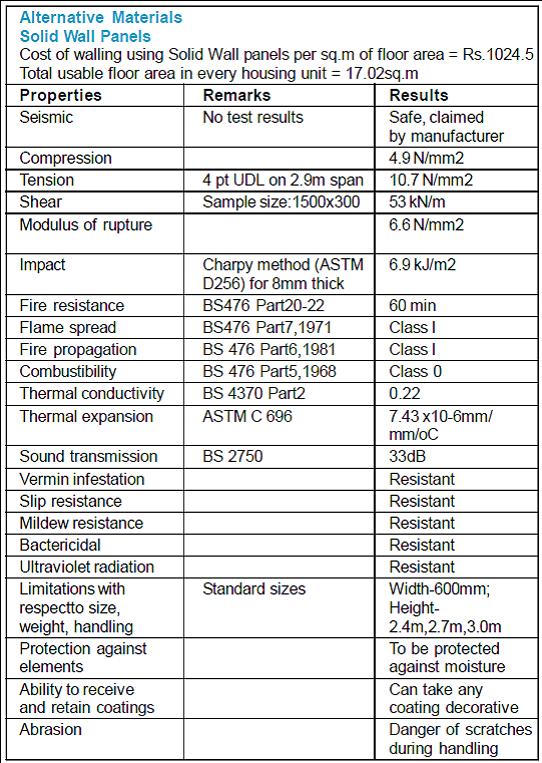

Solid Wall panels

Though the cost of construction is lower than that of RCC, there will be an increase in cost as, these are just walling panels. They are non-loadbearing panels. So, there is requirement of a structural system of either RCC or steel to transfer the dead and live loads to the ground. The usable floor area is more.

They are more durable than other bricks and blocks. They offer more comfortable stay than RCC walls.

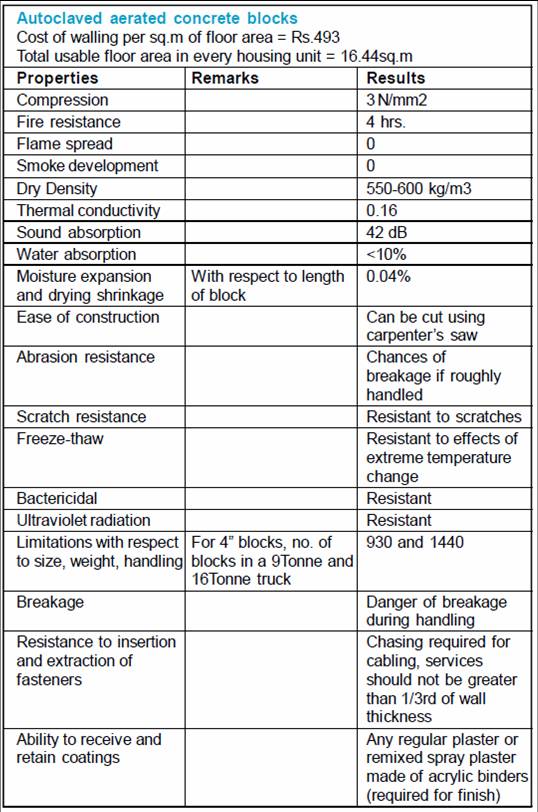

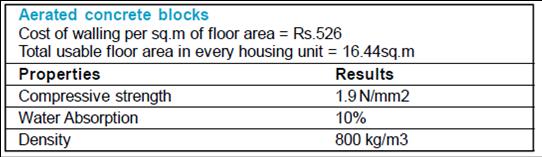

Autoclaved Aerated Concrete blocks

The cost of Autoclaved Aerated concrete blocks is among the lowest of the materials considered. But the cost of plastering will increase the finishing costs involved. The usable floor area when using non-loadbearing blocks will be the same as that with RCC walls.

Low density will reduce the dead load  on the structure and reduce the cost of the structural framework. Also, the compressive strength of the blocks is higher than other building components considered. They will offer a comfortable stay. on the structure and reduce the cost of the structural framework. Also, the compressive strength of the blocks is higher than other building components considered. They will offer a comfortable stay.

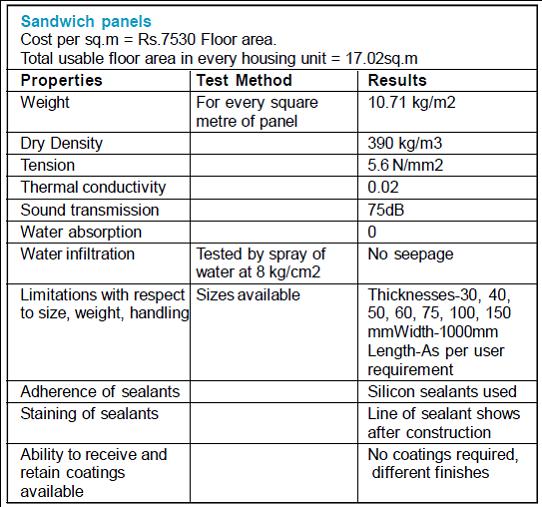

Continuous sandwich panels

Continuous Sandwich panels have a high construction cost. Even if they dont require any finishing coat on the surface, the cost of walling per sq.m of floor area is more than the cost of RCC walling and the finishing costs combined. The usable floor area is the second highest among materials considered. The density of the panels is the lowest among those considered. So, the cost of structural framing is considerably less. So, these panels are mostly used for industrial walling purposes where they use structural steel. The water absorption is nil, this increases the durability of the material.

They are suitable for places that have extreme temperatures. They should be used in places where the surroundings are quiet. Using these panels with a RCC structure is not cost-effective. But if the structural frame is of steel(eg PEB) then using these panels as a walling material is a good option.

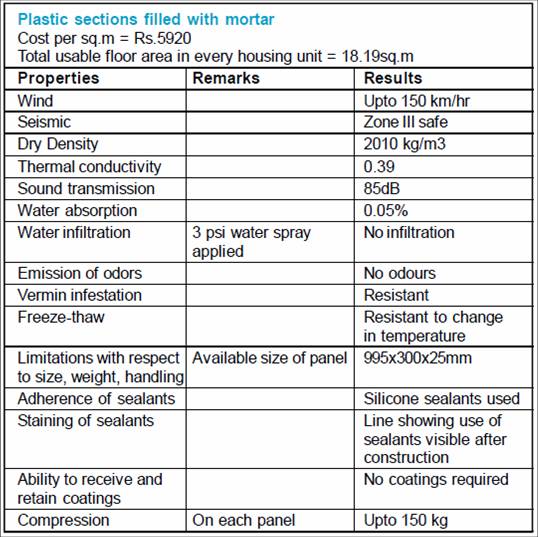

Mortar filled plastic panels

The cost is almost twice that of RCC walls. The compressive strength of the panels is immaterial as the loads will be borne by the steel framing. They are designed to sustain their own weight.

The usable floor area is the highest among the materials considered. The density of the panels is not much less than that of RCC. But the dead load on the structure will be less as the thickness of the panels is very less. They have almost 0 per cent water absorption if the joints are sealed properly. They have a low thermal conductivity. They should be preferably used in places where the surroundings are quiet.

Similar to continuous sandwich panels, their use is justified with steel  framing and in areas where conventional construction is difficult due to topography etc. framing and in areas where conventional construction is difficult due to topography etc.

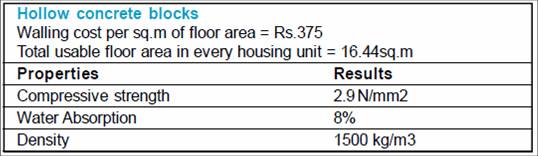

Hollow Concrete blocks

The cost of construction with hollow concrete blocks is the least among all materials considered. Even though the finishing costs will increase due to plastering coat, the cost will be less than the cost incurred for RCC walls. The usable floor area will be similar to the existing system of RCC walls.

The density of the blocks is higher than many of the materials considered but lesser than that of RCC. So, the cost for the structural frame will increase.

The compressive strength of the blocks is less than that of burnt clay bricks used conventionally.

Aerated Concrete blocks

The cost of construction with aerated concrete blocks is the lowest. Similar to hollow blocks, the finishing cost will be higher due to plastering etc.

The density of these blocks is less than that of hollow blocks but higher than autoclaved aerated concrete blocks. So, cost of structural frame will be higher. Floor area available will be equal to that with the existing system. The compressive strength of the blocks is the lowest among the building components considered. q Aakash Bagchi

abagchi@devalt.org Back to Contents |